EPDM O-ring seals play a critical role in many industries by preventing leakage of both liquids and gases. These seals are essential to keep machines and systems operating. EPDM means Ethylene Propylene Diene Monomer, which is a unique type of rubber with some cool-properties. It is durable, and can withstand the elements and temperature variations. Hence, EPDM O-ring seals are very advantageous in various environments. These seals can be found everywhere including in cars, chemical factories, construction sites, and manufacturing plants, as they are capable to function in a wide range of environments. Perhaps most impressively, these seals are able to operate at temperatures as low as -40°F and as high as 300°F—which means they are perfect for absolutely frigid or extremely hot conditions.

EPDM O-ring seals have several advantages over other types of seals, such as nitrile, silicone, and fluorocarbon. To begin with, EPDM O-ring seals are immune to a range of damage from things such as water, steam, UV light, ozone, chemicals and rust. That resistance gives them great strength and long lifespans. Because they withstand these conditions, they are often selected for critical applications. Next these seals have incredible sealing capabilities. They keep liquids and gases from leaking out, which is crucial for the function of machines and systems. Systems that work better can save energy and lower costs for the companies that use them, too. Third, EPDM O-ring seals are environmentally friendly. They are fabricated from eco friendly and recyclable materials. This is a relevant point for numerous companies at present. Last but not least, EPDM O-ring seals are the most economical compared to the sealing materials. As a result, they are a common choice for businesses requiring high production of seals without breaking the bank.

O-rings made from EPDM are different from other O-rings, particularly in terms of their chemical resistance and temperature tolerance. Nitrile O-ring seals, for example, excel at handling oils and fuels, yet when faced with high temperatures, they have to throw in the towel. Silicone O-ring seals, on the contrary, suits high-temperature situations yet do not interact properly with harsh chemicals. It is this combination of durability and flexibility that makes EPDM O-ring seals some of the best in the business, as they can withstand both high temperatures and tough chemicals. Compared with other seals, they have higher resistance against water and steam, so they're ideal in systems such as HVAC (heating, ventilation, and air conditioning), plumbing systems, and water purification processes. This makes EPDM O-ring seals one of the popular options for many applications.

EPDM O-ring seal is widely used in the automotive and manufacturing industries because to its good sealing properties and flexibility. In cars, these seals can be found in a number of systems including powertrain systems like engine cooling system, transmission, fuel system and HVAC systems. They are essential for stopping leaks of fluids that are critical to the function of the performance, such as coolant, oil, and fuel. Some of these fluids are vital to how the engine operates, and if they leak, it would prove disastrous (engine failure or lowered fuel efficiency) pretty quickly. And that's why good seals are essential for the health of the vehicle. Factories use EPDM O-ring seals in chemical processing, food processing, pharmaceuticals, and water treatment plants in the manufacturing industry. They are significant to worker's safety as they prevent the dangerous chemicals from leaking to the environment through soil and groundwater contamination. EPDM O-ring seals prevent these leaks from harming people and damaging equipment.

Installation and maintenance of EPDM O-ring seals is very critical for efficient performance and longevity of the gasket assembly. Some of the best practices to be followed while installing and maintaining EPDM O-ring seals are:

Prepare the Surface: Prior to placing the seal, it is important that the surface on which you will place the seal is free of dirt or debris. To do this, it should be cleaned of dirt, dust and rust to a proper fit.

Step 4: Avoid Over-tightening- When installing the seal, avoid over tightening as this would be the common cause of failure in more than 90% of the cases. If the seal is too tight, it may start to warp or snap, allowing leaks.

Shanghai Chongfu Industry Co., Ltd. provides aggressive pricing while maintaining product quality. The company offers short shipping and delivery times, making it a reliable choice for customers who require quick turnaround times. Additionally, they ensure thorough inspection and testing of all products before shipment, ensuring that customers receive products in perfect condition.

The company utilizes top-tier raw materials, such as American DuPont PTFE, 3M (DYGON), and Daikin from Japan, to provide their diaphragms. This ensures stable, excellent quality that meets or exceeds industry standards. The company works closely with trusted manufacturers who employ advanced production equipment and rigorous testing instruments, enabling precise quality control throughout the supply chain.

With over 13 years of experience in the diaphragm pump industry, the company has developed extensive expertise in the sale of AODD (Air Operated Double Diaphragm) pump parts. They specialize in offering high-quality, reliable pump components, ensuring that their products meet industry standards and exceed customer expectations.

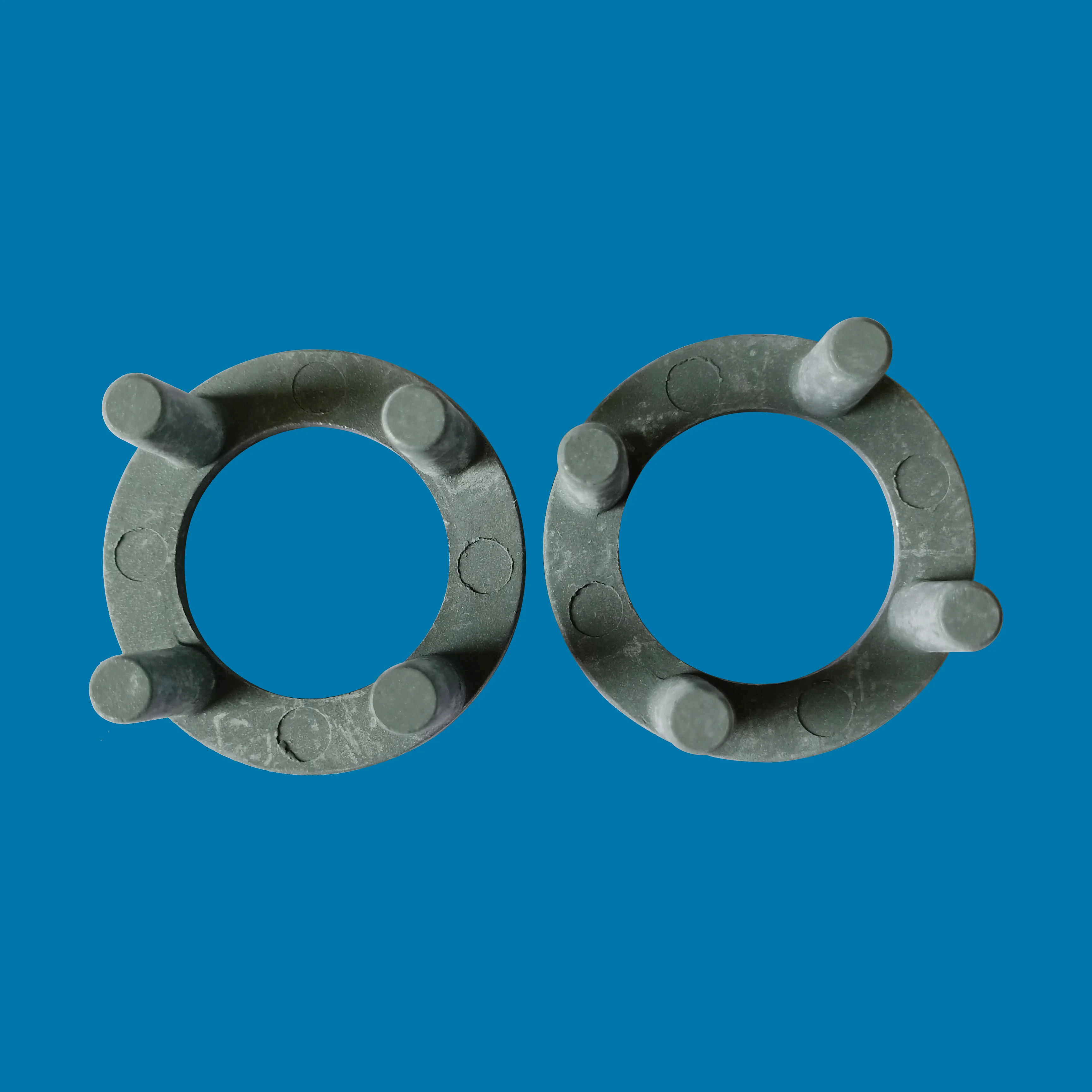

Shanghai Chongfu Industry Co., Ltd. offers a wide range of diaphragm pumps and accessories, including parts for world-renowned brands such as Wilden, Sandpiper, Almatec, Yamada, Graco, Blagdon, and Veresmatic. Their product catalog includes diaphragms, valve seats, ball valves, air valve assemblies, center bodies, shells, manifolds, shafts, mufflers, and repair kits, providing customers with a comprehensive selection of parts and pumps for various industrial needs.