Metering diaphragm pumps are specific apparatus widely used in different industries. These pumps are significant because they help liquids move from one place to another. Let's explore how these pumps operate, and why they are beneficial.

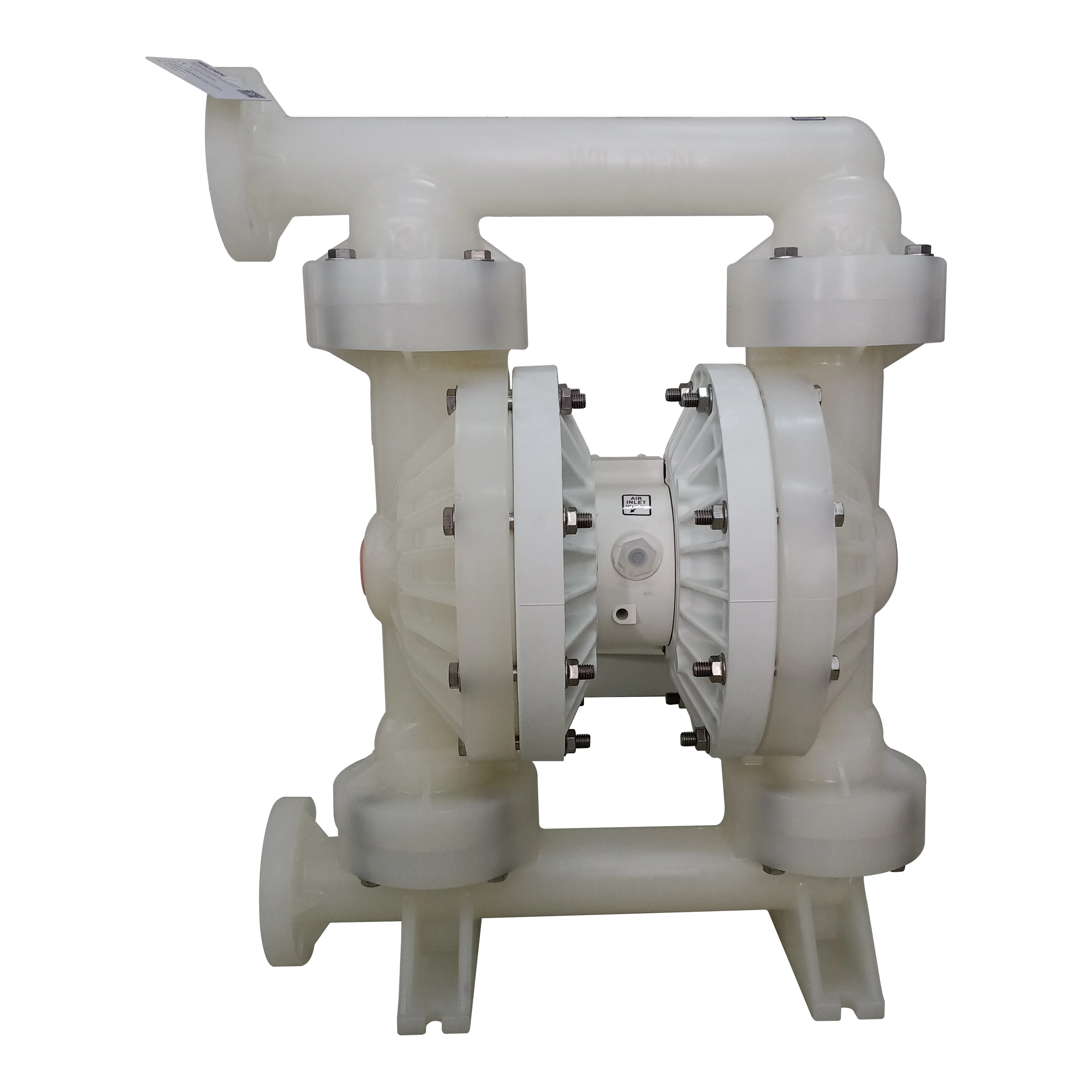

A air operated metering pump pushes liquid through pipes with the help of a special rubber part called a diaphragm. As the diaphragm moves forward and backward, it generates pressure to propel the fluid. This is how the pump transports liquid from one location to another. These pumps are also highly accurate and can pump a specific quantity of liquid at each stroke.

One major thing they can do is measure liquids with remarkable precision, and that opening and closing via a metering diaphragm pump. This is particularly advantageous in the case of industries where a precise quantity of liquid is to be transferred from one place to another. These pumps are dependable, and can run for long periods without failure. Furthermore, metering diaphragm pumps can be effortlessly managed, an added bonus for various industrial application.

Precision dosing is about dispensing a very precise amount of liquid each time. You could use metering diaphragm pumps for this purpose, as they can control precisely the volume of the liquid. This is vital in fields where one tiny mistake can lead to serious problems. With its metering diaphragm pump, you know you will always be moving the correct amount of liquid with each and every stroke.

A metering diaphragm pump should be maintained to function properly throughout life. Routine upkeep includes searching for leaks, keeping parts clean and swapping out any worn parts. If there is something wrong with the pump, then some troubleshooting will be necessary to figure out what it is. This can involve inspecting for blockages, ensuring all connections are tight and testing the pump to determine if it operates as it should.

When selecting a metering diaphragm pump, consider the specific application you are performing. If you’re considering buying a transfer pump, you should weigh the pros and cons of each pump type and model to reach the most appropriate decision based on your intended use for it, how much liquid needs to be transferred, and the liquid itself. There are several different kinds of metering diaphragm pumps so be sure to choose the one that’s right for you. You can also get opinions from the professionals to assist you in choosing the right design.

Shanghai Chongfu Industry Co., Ltd. provides aggressive pricing while maintaining product quality. The company offers short shipping and delivery times, making it a reliable choice for customers who require quick turnaround times. Additionally, they ensure thorough inspection and testing of all products before shipment, ensuring that customers receive products in perfect condition.

With over 13 years of experience in the diaphragm pump industry, the company has developed extensive expertise in the sale of AODD (Air Operated Double Diaphragm) pump parts. They specialize in offering high-quality, reliable pump components, ensuring that their products meet industry standards and exceed customer expectations.

The company utilizes top-tier raw materials, such as American DuPont PTFE, 3M (DYGON), and Daikin from Japan, to provide their diaphragms. This ensures stable, excellent quality that meets or exceeds industry standards. The company works closely with trusted manufacturers who employ advanced production equipment and rigorous testing instruments, enabling precise quality control throughout the supply chain.

Shanghai Chongfu Industry Co., Ltd. offers a wide range of diaphragm pumps and accessories, including parts for world-renowned brands such as Wilden, Sandpiper, Almatec, Yamada, Graco, Blagdon, and Veresmatic. Their product catalog includes diaphragms, valve seats, ball valves, air valve assemblies, center bodies, shells, manifolds, shafts, mufflers, and repair kits, providing customers with a comprehensive selection of parts and pumps for various industrial needs.