DIAPHRAGM AIR COMPRESSOR PUMP — March 2019Welcome to the thrilling world of diaphragm air compressor pumps, young readers. They are specialized machines that are used to transfer air and other gases. That are useful in a great many jobs and industries, such as in healthcare, in which they assist with medical equipment; in manufacturing, in which they aid in product creation; and in construction, in which they have help build. Let’s take a closer. at how these pumps function, and why they matter.

How a diaphragm air compressor pump works: A diaphragm air compressor pump uses a special part called a diaphragm. It’s a soft and flexible piece that plays a crucial role in pushing and pulling air. Think of a balloon that can shift its shape. As the air compressor diaphragm goes back and forth, it creates a space to pull air in then pushes it out of the pump. It is similar to the way you inhale and exhale. It is a motor that makes the diaphragm move, and without the motor, the diaphragm would be useless.

As the diaphragm pulls air in, it creates a vacuum: There’s less air in the pump. This creates a vacuum that draws more air from the outside. Then, whatever is sent through the diaphragm when it pushes air out goes where it needs to go, whether that be a machine or a different area. Thus this forward and backward motion of diaphgram compression pump helps most efficiently in pumping air, as well as gasses.

Proper cleaning of your diaphragm air compressor pump is one key aspect to maintaining your equipment. In the end, over a long term dust, dirt and other impurities create on the diaphragm and other passing where the fluid moves parts on the pump. This build-up can cause the pump to be less effective and even malfunction. When you clean the pump continuously, you can prevent dirt from slowing it down. It’s like cleaning up your room; a clean space will make it easier for you to find stuff and allows everything to function better.

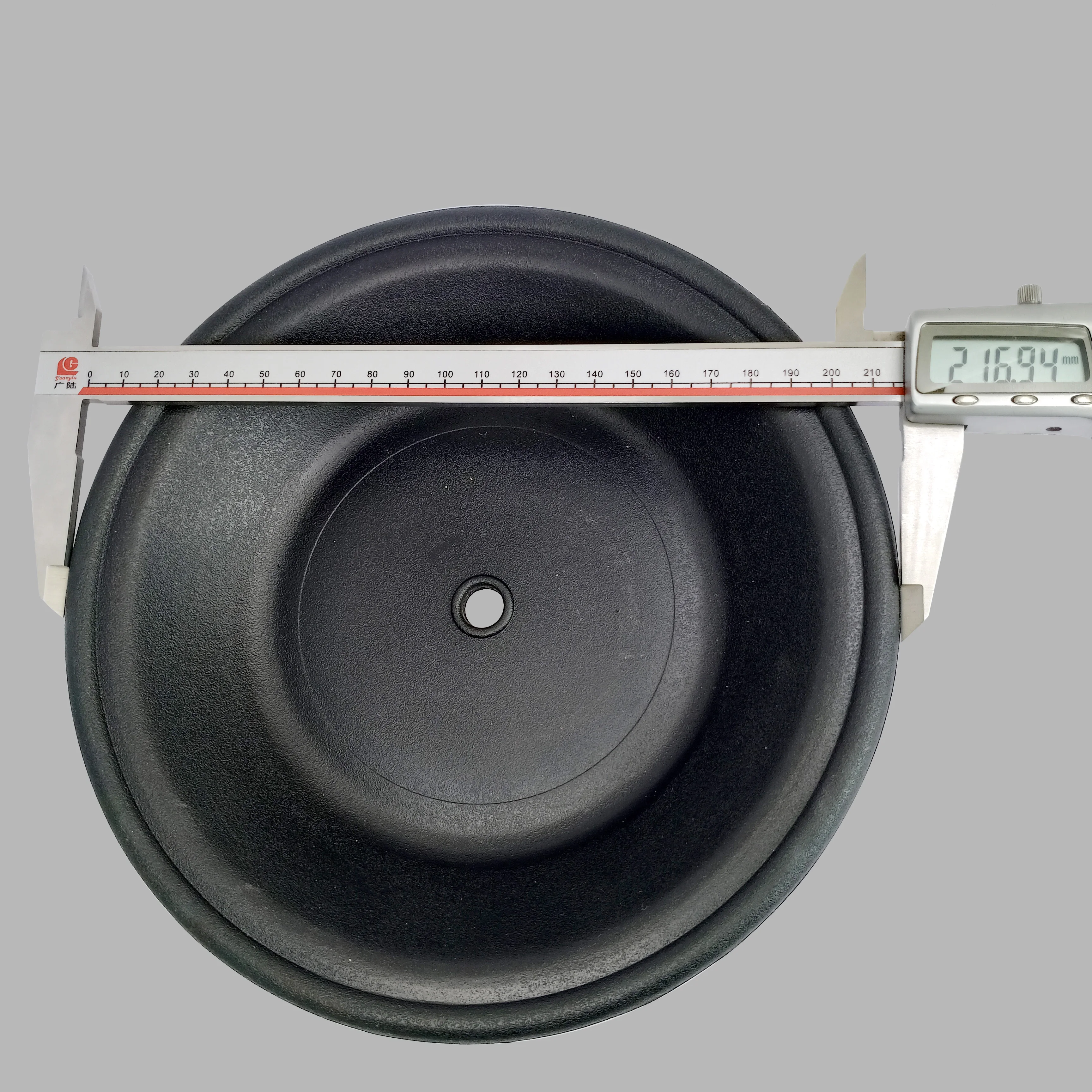

Below are several things to consider while choosing the right size pump. The air compressor pressure switch rubber diaphragm first thing to consider is how much air you need to move. Secondly consider the actual pressure you are trying to create. Air movement is crucial because it moves the air, which is where it is supposed to go. Lastly, consider what kind of gas you're putting in your car. Various body fluids might call for unique types of pumps, so it is ideal you comprehend what you require before you make your choice.

It’s easy to make some mistakes even if you take perfect care of your diaphragm air compressor pump. A common mistake is failing to replace worn-out or broken parts. As your shoes wear out over time, so do the parts of your pump. Failing to replace these worn or broken components can lead to your pump failing or performing poorly. You do need to get your pump serviced regularly and replace parts when needed.

Using the wrong type of oil or lubricant is another common mistake. Just like oil helps a pump run smoother, as it is used to lubricate the parts of a door hinge. Choosing diaphragm pumps incorrect oil can damage your pump and reduce its operational life. This may vary for different pumps, so always refer to the manufacturer’s instructions to see what type of oil, if any, is best for your pump. These steps will help your pump not only last longer, but be more effective.

Shanghai Chongfu Industry Co., Ltd. offers a wide range of diaphragm pumps and accessories, including parts for world-renowned brands such as Wilden, Sandpiper, Almatec, Yamada, Graco, Blagdon, and Veresmatic. Their product catalog includes diaphragms, valve seats, ball valves, air valve assemblies, center bodies, shells, manifolds, shafts, mufflers, and repair kits, providing customers with a comprehensive selection of parts and pumps for various industrial needs.

Shanghai Chongfu Industry Co., Ltd. provides aggressive pricing while maintaining product quality. The company offers short shipping and delivery times, making it a reliable choice for customers who require quick turnaround times. Additionally, they ensure thorough inspection and testing of all products before shipment, ensuring that customers receive products in perfect condition.

With over 13 years of experience in the diaphragm pump industry, the company has developed extensive expertise in the sale of AODD (Air Operated Double Diaphragm) pump parts. They specialize in offering high-quality, reliable pump components, ensuring that their products meet industry standards and exceed customer expectations.

The company utilizes top-tier raw materials, such as American DuPont PTFE, 3M (DYGON), and Daikin from Japan, to provide their diaphragms. This ensures stable, excellent quality that meets or exceeds industry standards. The company works closely with trusted manufacturers who employ advanced production equipment and rigorous testing instruments, enabling precise quality control throughout the supply chain.