Air compressors assist us with a variety of tasks that range from inflating tires to making tools function. They're a very handy machines! Perhaps you wonder how these machines work, though. Deep inside an air compressor, there is a manifold, and in That, there is something perhaps most important for the Manifold, Hence called Rubber Diaphragm. If these words seem too grand or scary, no problem! We will simplify everything and explain in layman's terms.

Air compressor pressure switch is a very important part. It regulates the amount of air that is contained in the compressor tank. Why is this important? Well, it can be dangerous if there is too much air in the tank! The pressure switch is what actually tells the compressor to stop adding any more air, lest we get a situation where the tank gets too full and bad things happen.

Next, I want to ask you about the rubber diaphragm. This section is essentially the muscle of the pressure switch. It pushes on a small metal lever attached to a switch that turns the compressor on and off. Think of how your muscles work to move your body; that is how the rubber diaphragm works! Without the rubber diaphragm, the compressor wouldn’t be told when to stop filling the tank. Which is why the rubber diaphragm, is very critical to helping protect everything and functioning properly.

Like many moving parts in life, the rubber diaphragm can wear out over time. That means it can get outdated and wont work as well as it did. That’s why it’s really important to take care of it and get it checked regularly.

If you have an air compressor, one thing you can do to take care of it is to check the pressure gauge. This is sometimes called a "manometer" and helps you know how much air is actually in your compressor. If the pressure gauge does not display the correct values, this may indicate a malfunctioning pressure switch. And inspect the rubber diaphragm frequently for cracks or signs of damage. If you find anything that seems wrong, it’s wise to correct it immediately.

Neglecting your pressure switch can result in damage or malfunction. This can be quite risky as the compressor could behave differently than you anticipate. So, keep checking everything to work right for the compressor safety!

At times, your air compressor may not function properly. This may be due to a pressure switch diaphragm. Another common issue is if the compressor won’t turn off when it should be. It could be the rubber diaphragm has a hole in it or is worn. When this occurs, the compressor continues to work despite being full of air.

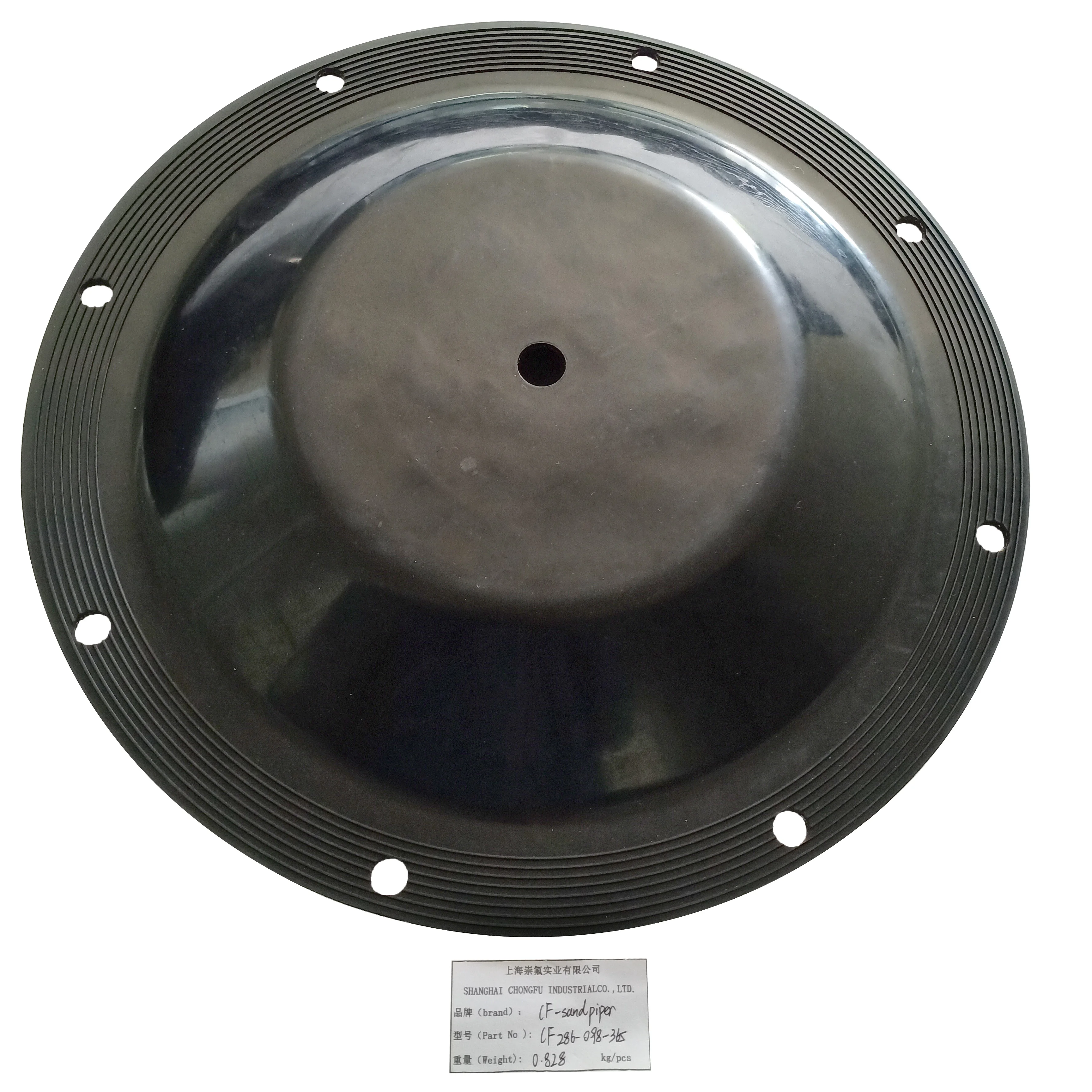

Shanghai Chongfu Industry Co., Ltd. offers a wide range of diaphragm pumps and accessories, including parts for world-renowned brands such as Wilden, Sandpiper, Almatec, Yamada, Graco, Blagdon, and Veresmatic. Their product catalog includes diaphragms, valve seats, ball valves, air valve assemblies, center bodies, shells, manifolds, shafts, mufflers, and repair kits, providing customers with a comprehensive selection of parts and pumps for various industrial needs.

With over 13 years of experience in the diaphragm pump industry, the company has developed extensive expertise in the sale of AODD (Air Operated Double Diaphragm) pump parts. They specialize in offering high-quality, reliable pump components, ensuring that their products meet industry standards and exceed customer expectations.

Shanghai Chongfu Industry Co., Ltd. provides aggressive pricing while maintaining product quality. The company offers short shipping and delivery times, making it a reliable choice for customers who require quick turnaround times. Additionally, they ensure thorough inspection and testing of all products before shipment, ensuring that customers receive products in perfect condition.

The company utilizes top-tier raw materials, such as American DuPont PTFE, 3M (DYGON), and Daikin from Japan, to provide their diaphragms. This ensures stable, excellent quality that meets or exceeds industry standards. The company works closely with trusted manufacturers who employ advanced production equipment and rigorous testing instruments, enabling precise quality control throughout the supply chain.