- Introduction

Introduction

|

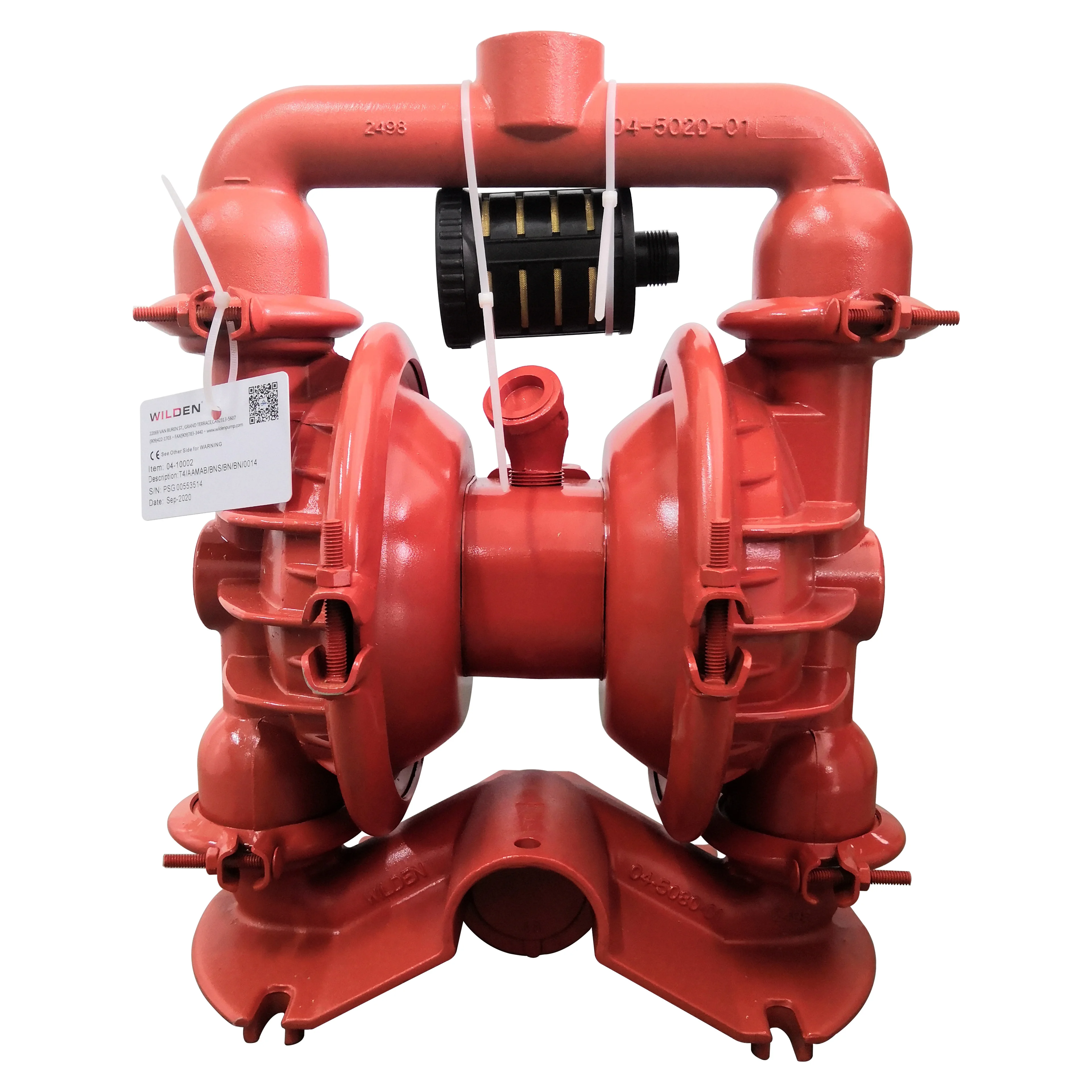

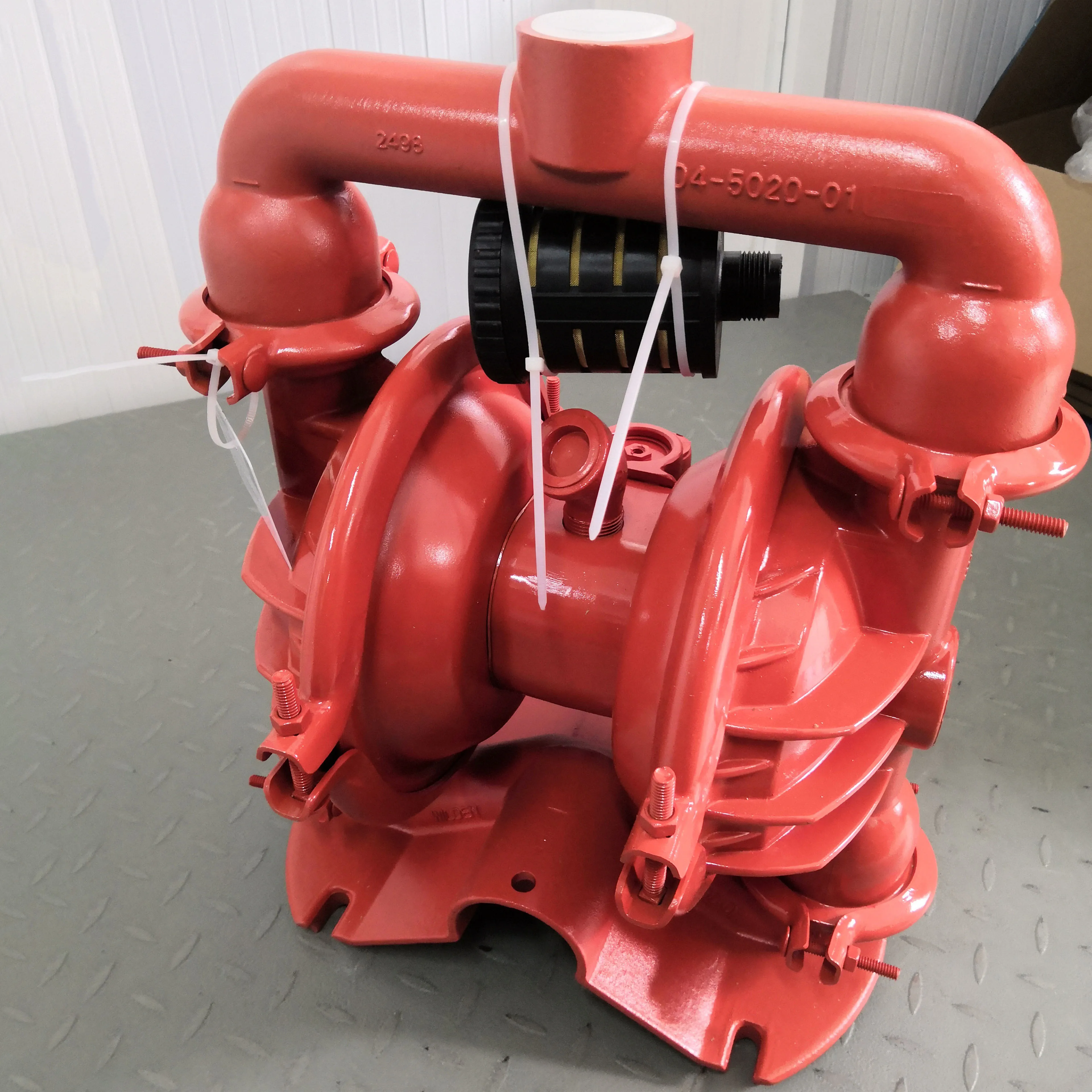

MODEL

|

T4/AAMAB/BNS/BN/BN/0014

|

|

BRAND

|

Chongfu

|

|

Shell material

|

Aluminum Alloy

|

|

Diaphragm material

|

BUNA Diaphragm

|

|

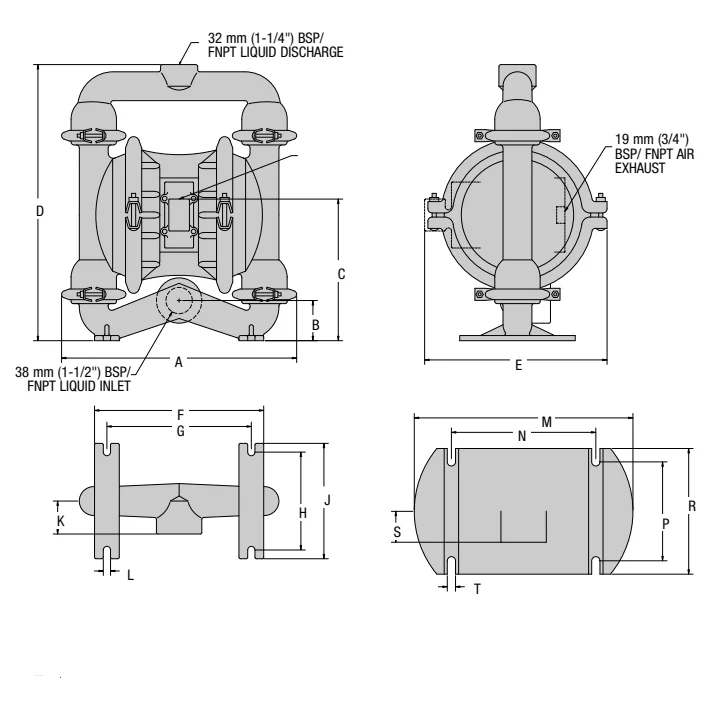

Medium outlet size

|

1 1/4 inch BSP

|

Pneumatic Diaphragm Pump Advantages:

* Idling ,Self-priming , Submerse capability.

* Provide stall-free, ice-free zero leak operation.

* Epoxy-coated air section for tough environmental conditions.

* Low shear force , not easy to damage the material structure.

* Bolt joint design provides even sealing pressure for optimal performance

* Modular air valve,low pulsation operation,providing smooth and rapid changeover.

* No electricity . It's safe and realiable while using in the flammable and explor place .

* Diversity of material,no rotating parts,applicable to various erosive situations.

* Can pump corrosive , volatile, flammable, poisonous fluids with particles and high viscosity.

* Delivery lift and flow can pass the pneumatic valve open to realize the stepless adjustment.

* Provide stall-free, ice-free zero leak operation.

* Epoxy-coated air section for tough environmental conditions.

* Low shear force , not easy to damage the material structure.

* Bolt joint design provides even sealing pressure for optimal performance

* Modular air valve,low pulsation operation,providing smooth and rapid changeover.

* No electricity . It's safe and realiable while using in the flammable and explor place .

* Diversity of material,no rotating parts,applicable to various erosive situations.

* Can pump corrosive , volatile, flammable, poisonous fluids with particles and high viscosity.

* Delivery lift and flow can pass the pneumatic valve open to realize the stepless adjustment.

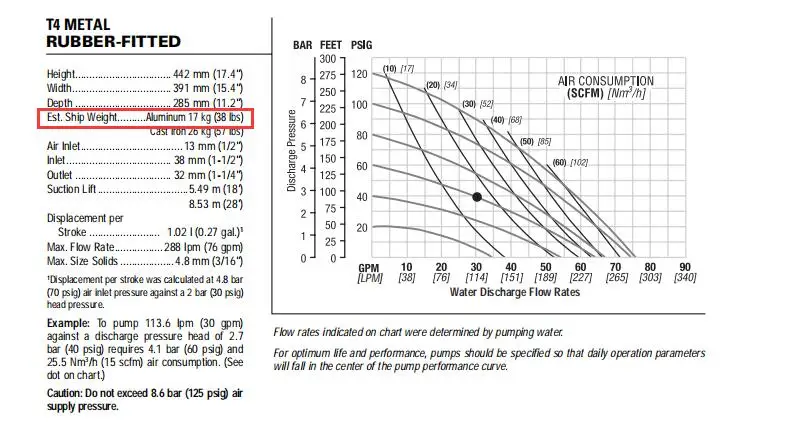

Pneumatic diaphragm pump data

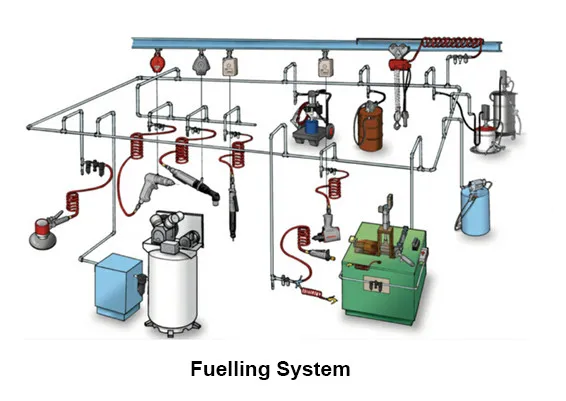

Air-Operated Diaphragm Pum Application

air-driven diaphragm pumps Widely used in the transport of diesel, petrol, gear oil, hydraulic oil ,etc .Can effectively carry and distribute lubricant oils to machinery as part of an automatic lubrication system.

can deal with all kinds of corrosive, volatile, flammable, poisonous fluids with particles and high viscosity.

1.The pump can suck the peanut, pickles, tomato slurry, red sausage, chocolate, hops and syrup etc.

2. The pump can suck the paint, pigment, glue and adhesive etc.

3. The pump can suck various glazed slurries of tile, porcelain, brick and chinaware etc.

4. The pump can suck various grinding materials, corrosive agent and clean the oil dirt etc.

5. The pump can suck various toxin and flammable or volatility liquid etc.

6. The pump can suck various wedge water, cement slurry and mortar etc.

7. The pump can suck various strong acid, alkali and corrosive liquid etc.

8. It can be used as a front-step tranmission device of the solid and liquid separation equipment.

2. The pump can suck the paint, pigment, glue and adhesive etc.

3. The pump can suck various glazed slurries of tile, porcelain, brick and chinaware etc.

4. The pump can suck various grinding materials, corrosive agent and clean the oil dirt etc.

5. The pump can suck various toxin and flammable or volatility liquid etc.

6. The pump can suck various wedge water, cement slurry and mortar etc.

7. The pump can suck various strong acid, alkali and corrosive liquid etc.

8. It can be used as a front-step tranmission device of the solid and liquid separation equipment.

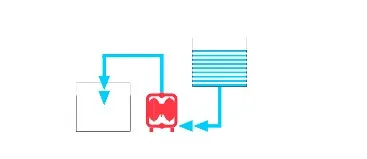

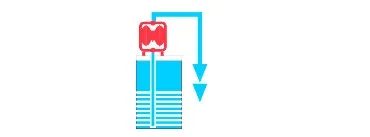

Air-Operated Diaphragm Pump Installation

pumps are suitable for an endless variety of applications . Our pumps can be deployed in fixed installations within a process flowsystem, or used as portable or mobile units that can be transported to where it is to be used.

Pump, self-priming

pumps are dry self-priming. Depending on the pump specification a suction lift of up to 8 m

pumps are dry self-priming. Depending on the pump specification a suction lift of up to 8 m

Pump with positive suction

Depending on the pump type, the suction side inlet pressure may need to be limited to a max. pressure

Depending on the pump type, the suction side inlet pressure may need to be limited to a max. pressure

Pump, submerged

pumps can be totally submerged in the pumped medium. The exhaust outlet must remain above the fluid level.

pumps can be totally submerged in the pumped medium. The exhaust outlet must remain above the fluid level.

Pump for drums

pumps can be directly mounted on drums or containers.

pumps can be directly mounted on drums or containers.

Product Links

Our Exhibition

OUR CERTIFICATES

1,Are you trading company or manufacturer?

Regarding seals; We are a manufacturing factory, such as; Diaphragm, ball, ball seat, sealing ring, etc

Regarding pumps, we are a sales company and the brand of the pump; Wilden, aro, sandpiper, etc

2,What is your MOQ?

MOQ may vary by customer's special requirement; we try our best to meetyour business requirement.

3, Can you provide samples?

Of course we can, and some of them are free, but the shipping cost you need pay.

4, I have a drawing, can you produce the same?

Yes, we can produce according to the drawing requirements. It would be better if you could provide samples

5,What are you usual terms of payment?

We have many payment methods, such as;L/C,Western Union,D/P,D/A,T/T,MoneyGram

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

DE

DE

EL

EL

HI

HI

IT

IT

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

SR

SR

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

AF

AF

MS

MS

GA

GA

HY

HY

AZ

AZ

KA

KA

BN

BN

LA

LA

MN

MN

NE

NE

KK

KK

UZ

UZ

KY

KY