Eine Zwerchfellpumpe ist eine besondere Maschine, die zur Übertragung von Flüssigkeiten von einem Punkt zum anderen verwendet wird. Sie funktioniert effektiv und wird daher in vielen Unternehmen eingesetzt. Diese Pumpe hatte Ein- und Ausgang, die wesentliche Teile sind. Diese Komponenten sind unerlässlich, weil sie es der Pumpe ermöglichen, ordnungsgemäß und effizient zu arbeiten.

Der Einlass ist der Eingang der Pumpe, wo das Flüssigkeitsmedium eintritt. Man kann ihn mit der Eingangstür der Pumpe vergleichen, die dem Medium den Eintritt in die Pumpe ermöglicht. Eine Pumpe erledigt viele kleine Aufgaben für Fluide; der Einlass wird verwendet, um das Medium aufzunehmen, wenn es gepresst wird, während der Auslass dafür sorgt, dass das Medium abgegeben wird. Es ist wie die Ausgangstür für das Flüssigkeitsmedium. Das Wissen darüber, wie der andere Teil funktioniert, hilft uns, einen Weg zu finden, die Pumpe reibungslos und ohne Störungen laufen zu lassen.

Die Position von Einlass und Auslass ist sehr kritisch für die Situation. Probleme können auftreten, wenn sie nicht richtig positioniert sind → die Pumpe funktioniert möglicherweise nicht gut. Du willst den Einlass tief haben, damit er leichter Flüssigkeit aufnehmen kann. Dies hilft sicherzustellen, dass die Pumpe ohne Hindernisse glatt die Flüssigkeit aufnehmen kann. Stelle sicher, dass der Auslass einen schnellen und leichten Fluss der Flüssigkeit ermöglicht. و اگر اوت لیت در درست جا نباشد، ان فشار زیا ی ایجاد می کند که ممکن است موجب آسیب به پمپ شود. Deshalb ist es ratsam, sich auf Experten zu verlassen, um diese Komponenten richtig einzurichten.

Luftblasen: Wenn der Einlass zu hoch ist, können Luftblasen entstehen. Eine häufige Ursache dieses Problems ist die Unfähigkeit der Pumpe, Flüssigkeit korrekt aufzunehmen. Um dies zu beheben, stelle sicher, dass dein Einlass so tief wie möglich platziert ist. Es wird der Leistung der Pumpe helfen.

Wenn die Düse nicht richtig positioniert ist, kann der Pumpenmotor unter Druck geraten. Dies schadet sowohl dem Pumpenmotor als auch dem System. Wenn dies die Ursache des Problems ist, entfernen Sie alle Verstopfungen in der Düse und stellen Sie sicher, dass sie sich in der richtigen Position befindet.

Falsche Durchflussrate: Wenn Einlass und Auslass nicht genau positioniert sind, kann der Flüssigkeitsdurchfluss falsch sein. Das könnte zu Pumpenschwierigkeiten führen. Daher ist es besser, wenn Sie einen Experten konsultieren, der Ihnen bei der Anpassung der Positionen beider Teile für eine bessere Leistung hilft.

Wenn man eine Zwerchfellpumpe optimal einsetzen will, muss man sehr vorsichtig sein, wie die Ein- und Auslassungen ausgerichtet sind. Sie wissen, wo Sie nach diesen Teilen suchen sollen, damit Sie die Flüssigkeiten im System besser optimieren können. Shanghai Chongfu ist Hersteller von hochwertigen Zwerchfellpumpen für verschiedene Branchen. Wir bieten Ihnen professionelle Beratung und Unterstützung, um sicherzustellen, dass Sie das Beste aus Ihrer Pumpe herausholen. Bevor Sie eine Pumpe auswählen, ist es wichtig, mit unseren Experten zu sprechen, damit Sie das für Ihre Situation beste Modell finden.

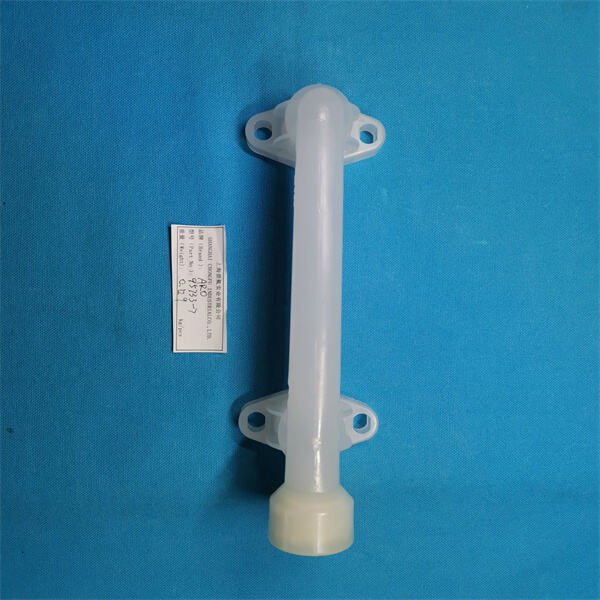

Shanghai Chongfu Industry Co., Ltd. bietet eine breite Palette an Membranpumpen und Zubehörteilen an, einschließlich Teile für weltbekannte Marken wie Wilden, Sandpiper, Almatec, Yamada, Graco, Blagdon und Veresmatic. Ihr Produktkatalog umfasst Membrane, Ventilsitze, Kugelventile, Luftventilbauwerke, Zentralkörper, Gehäuse, Manifolds, Wellen, Schalldämpfer und Reparatsätze, wodurch Kunden eine umfassende Auswahl an Teilen und Pumpen für verschiedene industrielle Anwendungen zur Verfügung gestellt wird.

Shanghai Chongfu Industry Co., Ltd. bietet aggressive Preise, während sie die Produktqualität aufrechterhalten. Das Unternehmen bietet kurze Liefer- und Versandzeiten, was es zu einer verlässlichen Wahl für Kunden macht, die schnelle Umlaufzeiten benötigen. Darüber hinaus stellen sie sicher, dass alle Produkte vor der Versendung gründlich geprüft und getestet werden, um sicherzustellen, dass Kunden Produkte in perfektem Zustand erhalten.

Das Unternehmen nutzt hochwertige Rohstoffe, wie amerikanisches DuPont PTFE, 3M (DYGON) und Daikin aus Japan, um ihre Membranen herzustellen. Dies gewährleistet eine stabile, exzellente Qualität, die den Branchenstandards entspricht oder sie übertrifft. Das Unternehmen arbeitet eng mit vertrauenswürdigen Herstellern zusammen, die moderne Produktionsausrüstungen und strenge Testinstrumente einsetzen, um eine präzise Qualitätskontrolle im gesamten Lieferungsprozess zu ermöglichen.

Mit über 13 Jahren Erfahrung in der Membranpumpenindustrie hat das Unternehmen umfangreiches Fachwissen im Verkauf von AODD (Air Operated Double Diaphragm)-Pumpenteilen entwickelt. Sie spezialisieren sich darauf, hochwertige, zuverlässige Pumpenkomponenten anzubieten und sicherzustellen, dass ihre Produkte den Branchenstandards entsprechen und die Erwartungen der Kunden übertreffen.

Urheberrecht © Shanghai Chongfu Industry Co., Ltd. Alle Rechte vorbehalten