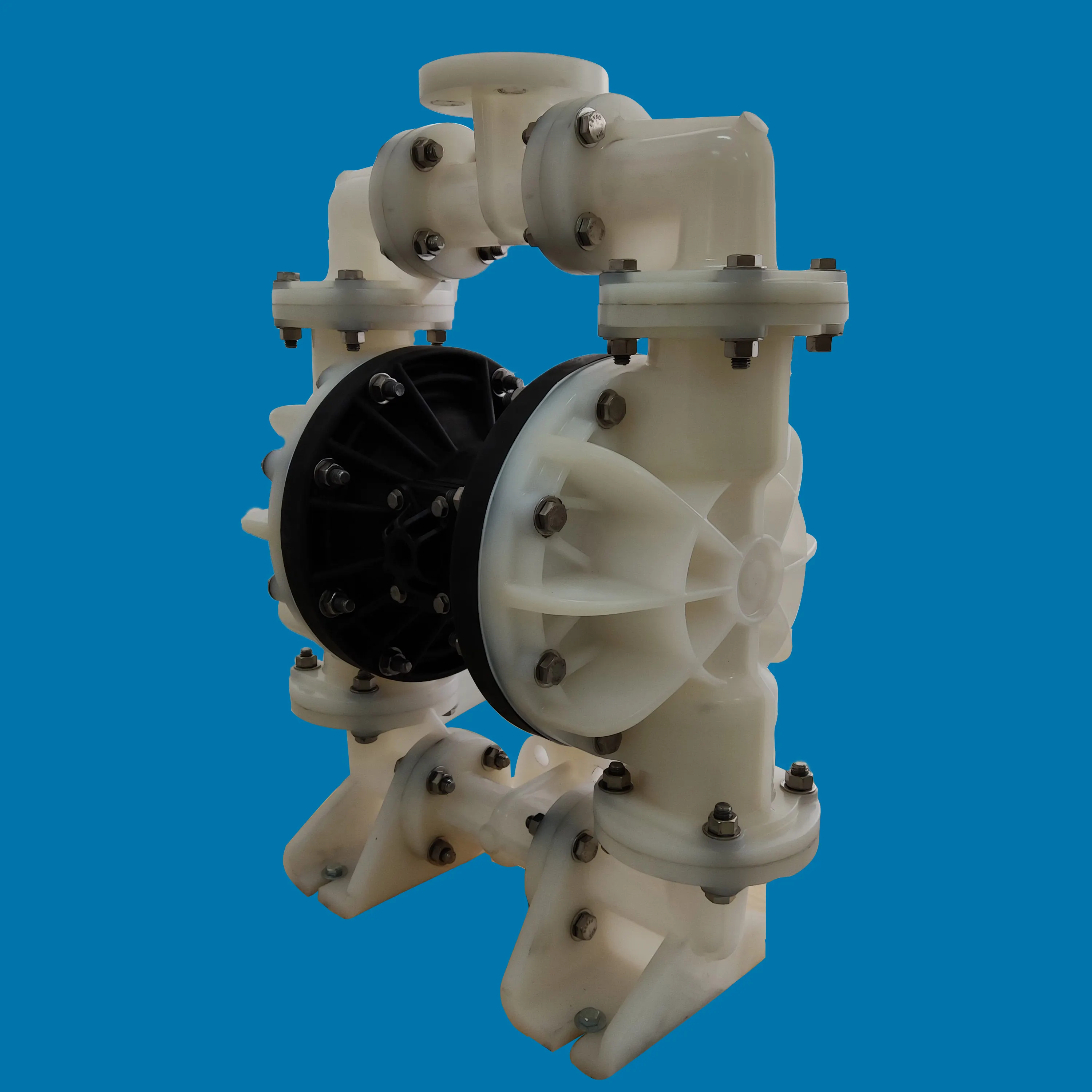

There are several reasons why Wilden air-operated diaphragm pumps are still considered reliable. The first is that they are uniquely engineered for extreme materials and extreme jobs. For instance, these pumps are compatible with viscous fluids which are difficult to transport, as well as slurries composed of solid particulates. They can also deal with tough materials that could easily damage other kinds of pumps. This versatility allows them to be implemented across various sectors, including chemical manufacturing plants, food and beverage processing sites, and wastewater treatment facilities.

These pumps are so negligible that they are extremely easy to use, which is another reason for their reliability. They operate with compressed air, so they don't require electricity to function. Having power sources that do not require electricity is useful as it enables them to be used in locations that may not have access to mains electricity. Moreover, it can also be easily repaired and maintained in good working condition should something ever go wrong with it. This is essential for companies that must rely on their equipment to function at all times.

The wide range of applications for wilden air-operated diaphragm pumps They can pump many kinds of liquids, such as acids, bases, and cleaning solvents. This makes them particularly valuable in sectors where safety and hygiene are prioritised. Other tasks such as helping to get food and beverage products such as milk, beer, and wine safely and efficiently is where they are also used.

These types of pumps are also capable of transferring solids, for example sand and gravel, in addition to liquids. This handy feature makes them highly beneficial in the construction business, as they are frequently employed to eliminate water from worksites and combine cement to develop strong structures. Additionally, the oil and gas field can use these pumps as well, where they can be used for aiding in waste management and for processes such as fracturing.

One of the best things about Wilden air-operated diaphragm pumps is their ease of maintenance. That is because they have very few moving parts. Unlike many other water pumps, they don’t have motors or bearings, which are mechanical parts that can break down over time and require replacement. In addition, they do not have seals, reducing the likelihood of leaks occurring.

These air-operated diaphragm pumps from Wilden operate by using air pressure to generate the movement. The pump on its behalf is a diaphragm which creates a vacuum that draws fluids into the pump. After the liquid is inside, the pump then forces the fluid out through a discharge port. It is a low cost and high efficiency process.

The diaphragms themselves are constructed from flexible materials—like rubber or plastic—that allows them to move easily. It is a very useful design to enable the pump to pump thick liquids and solid materials without getting obstructed or damaged. Wilden air-operated diaphragm pumps are effective for a variety of applications due to the combination of strong materials and smart design.

Shanghai Chongfu Industry Co., Ltd. provides aggressive pricing while maintaining product quality. The company offers short shipping and delivery times, making it a reliable choice for customers who require quick turnaround times. Additionally, they ensure thorough inspection and testing of all products before shipment, ensuring that customers receive products in perfect condition.

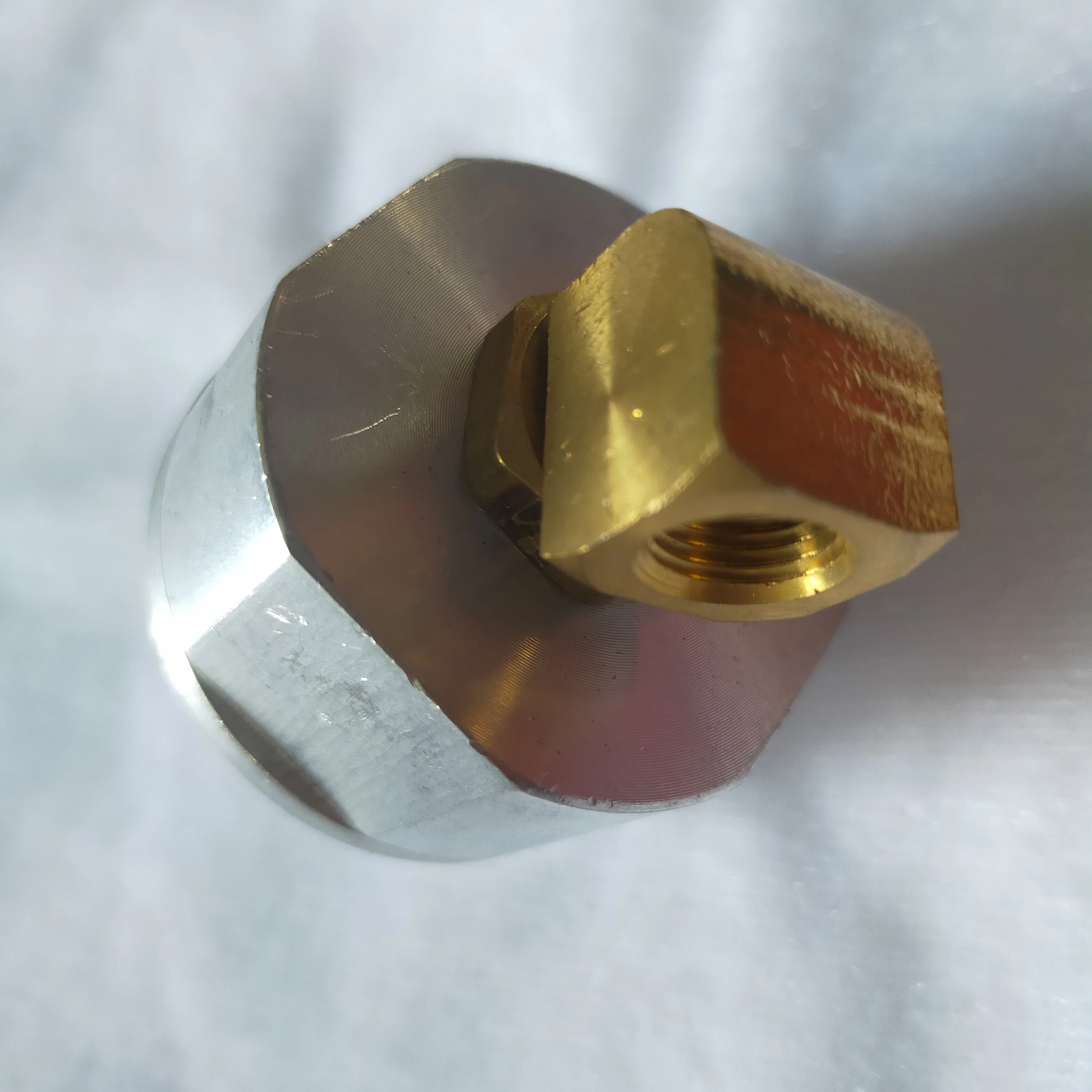

The company utilizes top-tier raw materials, such as American DuPont PTFE, 3M (DYGON), and Daikin from Japan, to provide their diaphragms. This ensures stable, excellent quality that meets or exceeds industry standards. The company works closely with trusted manufacturers who employ advanced production equipment and rigorous testing instruments, enabling precise quality control throughout the supply chain.

With over 13 years of experience in the diaphragm pump industry, the company has developed extensive expertise in the sale of AODD (Air Operated Double Diaphragm) pump parts. They specialize in offering high-quality, reliable pump components, ensuring that their products meet industry standards and exceed customer expectations.

Shanghai Chongfu Industry Co., Ltd. offers a wide range of diaphragm pumps and accessories, including parts for world-renowned brands such as Wilden, Sandpiper, Almatec, Yamada, Graco, Blagdon, and Veresmatic. Their product catalog includes diaphragms, valve seats, ball valves, air valve assemblies, center bodies, shells, manifolds, shafts, mufflers, and repair kits, providing customers with a comprehensive selection of parts and pumps for various industrial needs.