It is a specific type of synthetic rubber known as Nitrile NBR 70. That is created by man in a factory and not from trees or plants. It is made from two basic chemicals, acrylonitrile and butadiene. When combined, these chemicals create a substance that boasts several beneficial properties. Due to its excellent characteristics that allow its use in a vast range of applications, nitrile NBR 70 is widely used in the industry and automotive sector.

Oil and Fuels Resistant of Nitrile NBR 70 One of the key properties of Nitrile NBR 70 is its excellent ability to resist oil and fuels. This means that it would not break down or be damaged when oil or fuel comes in contact with it. It is also highly resistant to water, chemicals, and other liquids. These properties make Nitrile NBR 70 an excellent material for use in the manufacture of gaskets, seals, and other products requiring liquid resistance and strength. Because of this, it's ideal for use in any situation where leaks might occur.

Nitrile NBR 70 and Nitrile NBR 70 Have Long Life: Another very good thing about Nitrile NBR 70 is that it is very durable and has a long life. It resists damage while being constantly exposed to high pressure, extreme temperatures, and abrasion. The toughness is very critical especially in machine and engine where the part must be reliable. Nitrile NBR 70 is also capable of absorbing shock and vibration. That way, when it hits bumps or shakes, it can protect itself — and other parts of the machine — over time.

Nitrile NBR 70 has many advantages and that is why it is widely used in factory and automotive. Its resistance to all sorts of chemicals is one of the reasons why it is so popular. Things like acids, bases, and solvents fall into this category, some of which can be a hazard to other materials. Its resistance to these chemicals means that it can be used in many different environments. Nitrile NBR 70 also has decent electrical properties, allowing it to be manufactured as conductive or non-conductive as required.

Properties of this seal make Nitrile NBR 70 an ideal materialused for sealing in industrial applications. It is resistant to oil, fuels, chemicals, and water that can make it fit for use in difficult and rigorous factory environments. This means that it's also one of the best option in terms of chemical and heat resistance and doesn't break up quickly even at worse atmospheres which are present in a lot of the environments. And also, to add on top of that, it is strong and capable of withstanding high pressure and heat, which is incredibly important in industrial applications.

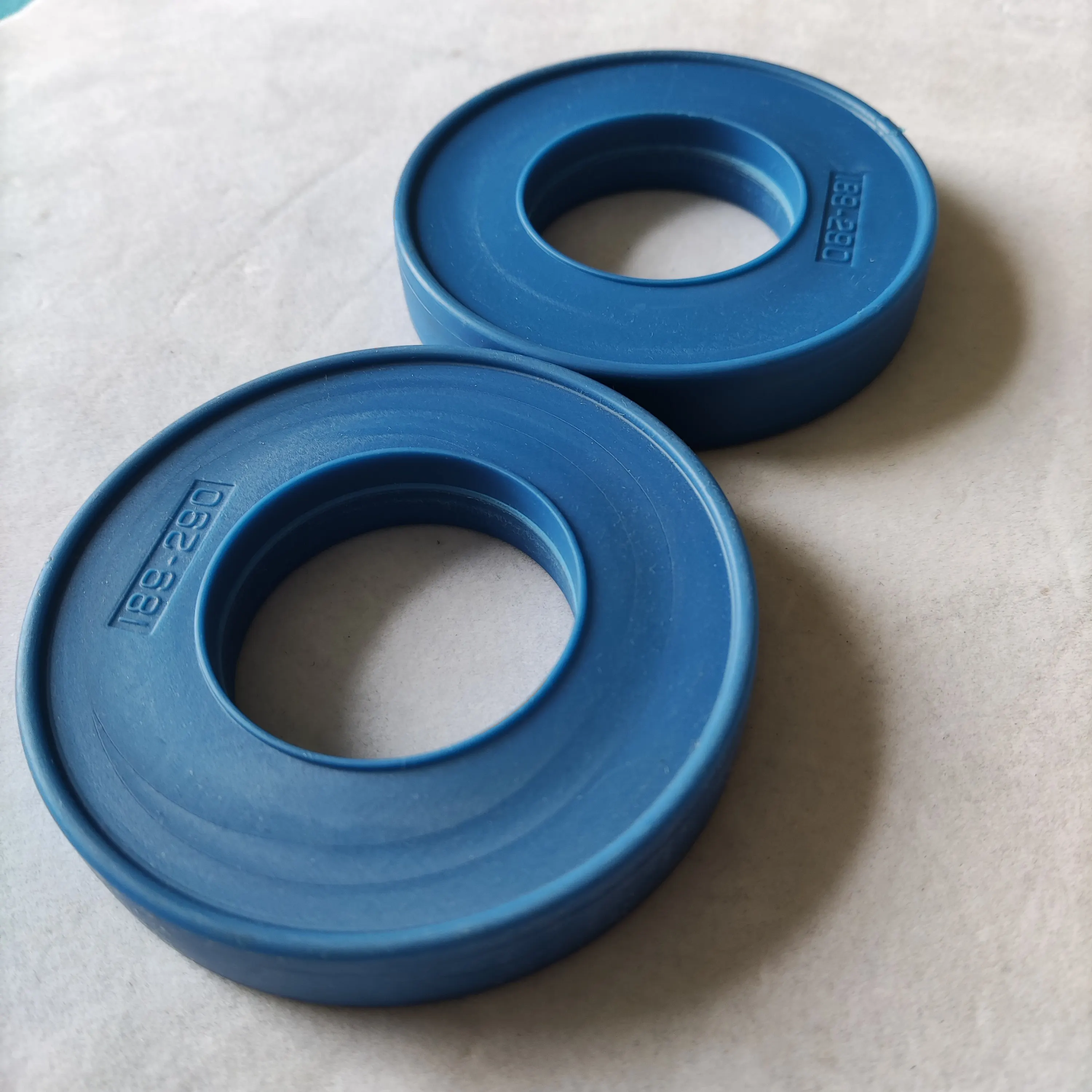

Nitrile NBR 70 is also common for use in O-ring production, one of the industrial sealing applications. O-rings are the small but critical components in seals for pipes, valves and other equipment to prevent leakages. [NOTE: Since this type of Nitrile NBR 70 is quite resistant to oil and chemicals, it is ideal for the construction of these O-Rings. This is key as machinery and equipment must do their thing with no leaks for safety and efficience.

One of the most coveted characteristics of Nitrile NBR 70 is its chemical resistance. It can resist many types of chemicals — acids, bases and solvents. That is from the industrial perspective, a perfect material for the chemical industry, where workers spend a lot of time standing over caustic chemicals that damage most other materials. Nitrile NBR 70 prevents this and helps keep your equipment safe and functional in less than ideal conditions.

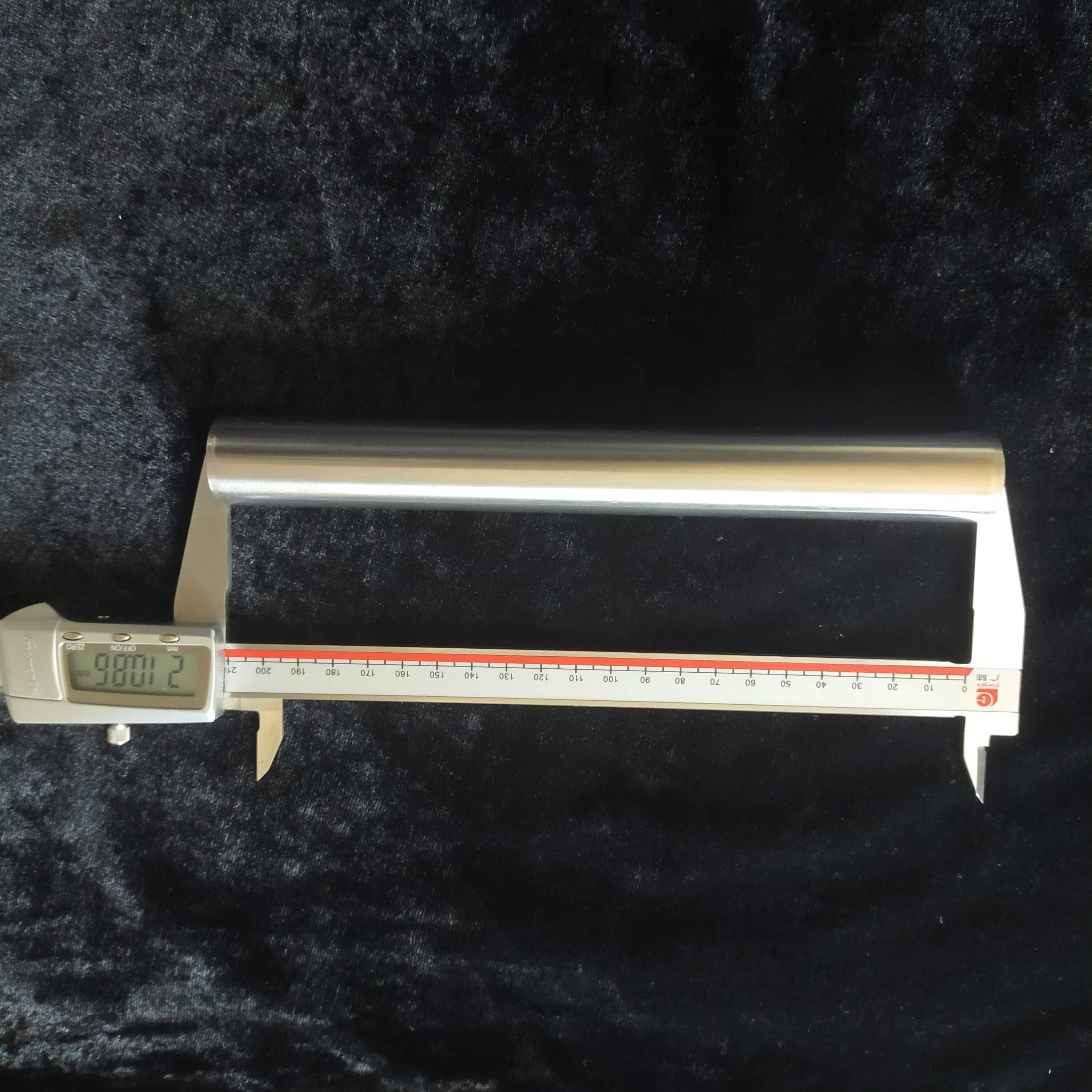

Shanghai Chongfu Industry Co., Ltd. offers a wide range of diaphragm pumps and accessories, including parts for world-renowned brands such as Wilden, Sandpiper, Almatec, Yamada, Graco, Blagdon, and Veresmatic. Their product catalog includes diaphragms, valve seats, ball valves, air valve assemblies, center bodies, shells, manifolds, shafts, mufflers, and repair kits, providing customers with a comprehensive selection of parts and pumps for various industrial needs.

With over 13 years of experience in the diaphragm pump industry, the company has developed extensive expertise in the sale of AODD (Air Operated Double Diaphragm) pump parts. They specialize in offering high-quality, reliable pump components, ensuring that their products meet industry standards and exceed customer expectations.

Shanghai Chongfu Industry Co., Ltd. provides aggressive pricing while maintaining product quality. The company offers short shipping and delivery times, making it a reliable choice for customers who require quick turnaround times. Additionally, they ensure thorough inspection and testing of all products before shipment, ensuring that customers receive products in perfect condition.

The company utilizes top-tier raw materials, such as American DuPont PTFE, 3M (DYGON), and Daikin from Japan, to provide their diaphragms. This ensures stable, excellent quality that meets or exceeds industry standards. The company works closely with trusted manufacturers who employ advanced production equipment and rigorous testing instruments, enabling precise quality control throughout the supply chain.