Mechanical diaphragm pumps are neat machines that make it easy to move liquids around! They do so using a special rubber part known as a diaphragm, which forces the fluid through the pump or pulls it through. You will find these pumps pretty much everywhere as well – on your local water treatment plant or in a local factory, or on your small farm. Here is more about how they work and why they matter.

Diaphragm pumps are excellent at pumping all types of liquids, from water to chemicals. They operate with a diaphragm, which is pretty much like a huge rubber sheet moving back and forth inside the pump. When the diaphragm goes down, it sucks the liquid into the pump. Then when it moves down again, it forces the fluid out of the pump. This helps to keep the liquid flowing smoothly.

3DollarValses n Off Hand.;coindlct ofc, 8FoldlnOffHand OxLSc oiji iOllc.-i 6 Six M rk'; 13MenofWurraanty lOOnAct leW iclity ''fltf arigureAmfamps 11 3Dollar alses n nificance did not Concealed leet r1LL ONLYithe MECHANICAL DRIVEN DIAPRAGM PUM? 14 That whom If Is withheld Where Mechanical Diaphragm Pumps Are Installed

Mechanical diaphragm pumps are ideal in so many tasks that they are applied in many different jobs. They are used, for instance, in factories hauling chemicals from one spot to another. They can also be employed on farms to water crops or in sewage treatment plants to shift dirty water. And since it can accommodate several types of liquids, it is very useful in many applications.

Why Should You Use Mechanical Diaphragm Pumps? One major reason is that they are adept at dealing with liquids that contain fine particles or solids. This is what makes them ideal for applications involving dirty liquids. They are also easy on the liquids they pump, which means they are easier on the product. Mechanical diaphragm pumps are also simple to regulate so many companies find them a wise investment.

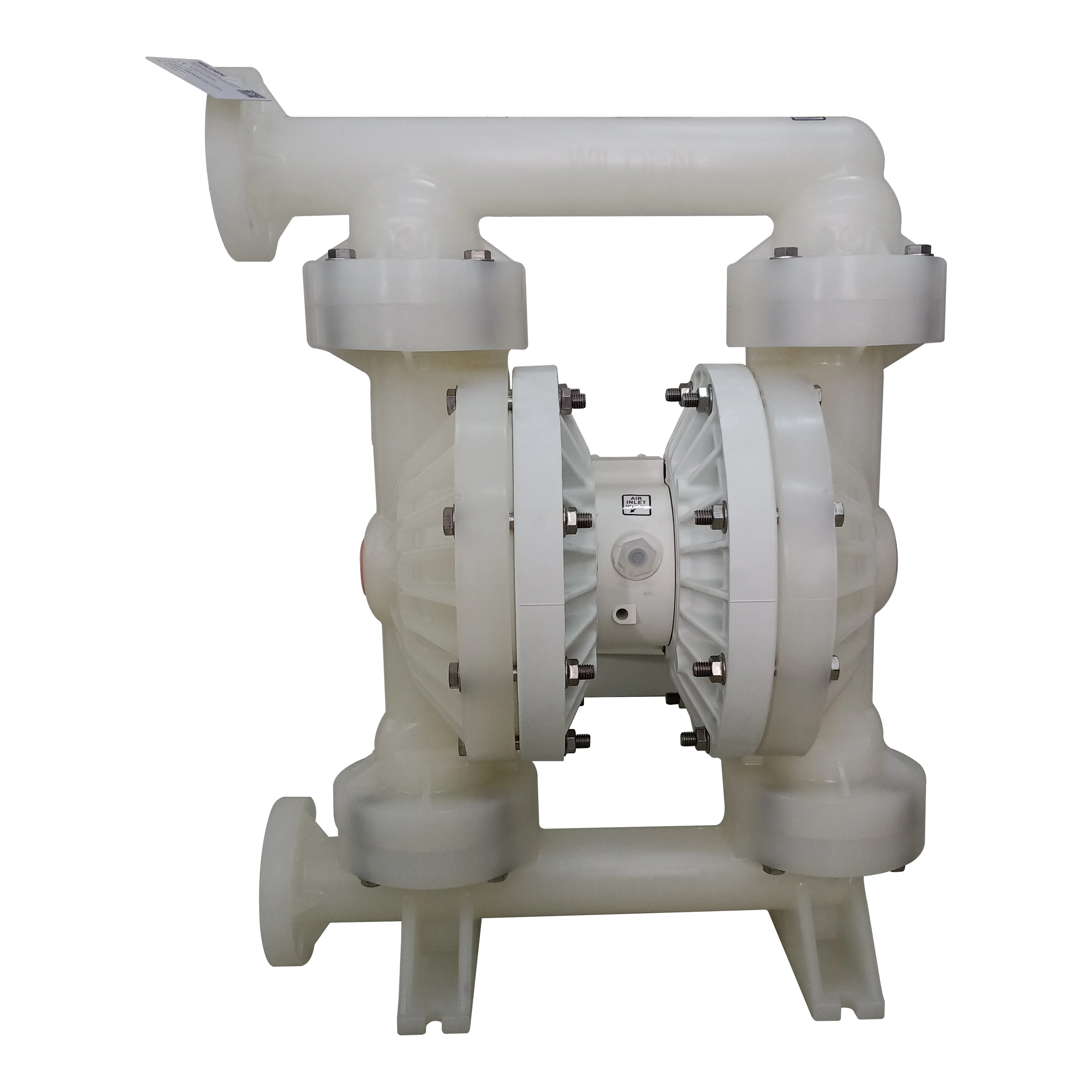

As basic as they may appear, aodd pumps are deceptively complex when it comes to the number of components involved. Key parts include the diaphragm — made often of rubber — that moves up and down, and the check valves that dictate how the liquid moves. There are also gates that open and close to allow the liquid to come in and out of the pump. All of these parts contribute to the pump operating properly.

Regular maintenance is necessary to maintain good operation of a mechanical diaphragm pump. One of them is inspecting the diaphragm for damage, cracks or tears. The diaphragm, if damaged, does not pump liquid correctly. You’ll also want to see if the valves open and close properly. If you keep the pump clean and properly lubricated seeing a long period of service out of it is easily attainable. With proper care, a mechanical diaphragm pump can continue to operate efficiently.

Shanghai Chongfu Industry Co., Ltd. provides aggressive pricing while maintaining product quality. The company offers short shipping and delivery times, making it a reliable choice for customers who require quick turnaround times. Additionally, they ensure thorough inspection and testing of all products before shipment, ensuring that customers receive products in perfect condition.

With over 13 years of experience in the diaphragm pump industry, the company has developed extensive expertise in the sale of AODD (Air Operated Double Diaphragm) pump parts. They specialize in offering high-quality, reliable pump components, ensuring that their products meet industry standards and exceed customer expectations.

Shanghai Chongfu Industry Co., Ltd. offers a wide range of diaphragm pumps and accessories, including parts for world-renowned brands such as Wilden, Sandpiper, Almatec, Yamada, Graco, Blagdon, and Veresmatic. Their product catalog includes diaphragms, valve seats, ball valves, air valve assemblies, center bodies, shells, manifolds, shafts, mufflers, and repair kits, providing customers with a comprehensive selection of parts and pumps for various industrial needs.

The company utilizes top-tier raw materials, such as American DuPont PTFE, 3M (DYGON), and Daikin from Japan, to provide their diaphragms. This ensures stable, excellent quality that meets or exceeds industry standards. The company works closely with trusted manufacturers who employ advanced production equipment and rigorous testing instruments, enabling precise quality control throughout the supply chain.