So what is the HNBR o ring? The name is long and complicated, but it’s actually a very important part that is used in a lot of different kinds of machines and devices. Shanghai Chongfu manufactures tough and quality HNBR o rings for all types of application and industries to improve/ function their machines.

There are great benefits of HNBR o rings which creates them a well-liked alternative in many industries. Our new puppies can be very strong and one reason we love them. They can withstand heat, oils and toxic chemicals. That is why they work great in harsh surroundings like in cars, oil and gas extraction and even airplanes. Hardy rubber nitrile o rings are exceptionally robust materials and resistant to pressure and heat degradation for long periods of time. As a result, they are very trustworthy for various machines intended to operate in extreme conditions.

So, what exactly is HNBR? HNBR (hydrogenated nitrile butadiene rubber) It is a specific type of synthetic rubber and it is created by combining nitrile rubber and butadiene rubber. Most rubber types have a double bond between carbon and carbon atoms, but what's special about HNBR is that during the manufacturing process, hydrogen is introduced into the rubber. This process is known as hydrogenation. Hydrogen strengthens and stabilizes the rubber greatly enhancing its heat and chemical resistance. That is why HNBR o rings are your very best choice for machines that need both strong and long-lasting seals.

With high-grade HNBR o rings, machines have a higher chance of performing better and having a longer life. For instance, HNBR o rings are regularly used in critical components like engines and fuel systems in the automotive sector. These components require seals that can handle extremely high temperatures and aggressive chemicals. This makes sure that there are no leaks or failures in the system and the cars can run smoothly, which is vital for safety and performance as well.

Likewise, in the oil and gas sector, many machinery such as valves and pumps should operate in very extreme conditions. These usually involve extreme heat and extreme pressure. HNBR o rings are engineered with these harsh conditions in mind, which is why they are ideal for this type of application. They’re also used in downhole drilling tools, which have to handle extreme heat and high pressure without a failure, keeping the whole show safe and efficient.

HNBR o rings can be used in various industries and applications. Hydraulic pistons use them to form seals that stop leaks. HNBR o rings are preferred for air conditioning systems due to their strength and resistance to ozone damage, allowing them to stop refrigerant leaks in the compressor and refrigerant lines, which keeps the system working efficiently. They are also used in factories and other industrial machinery to prevent leaks from pumps, motors, and hydraulic cylinders, ensuring that operations run smoothly and avoiding costly repairs.

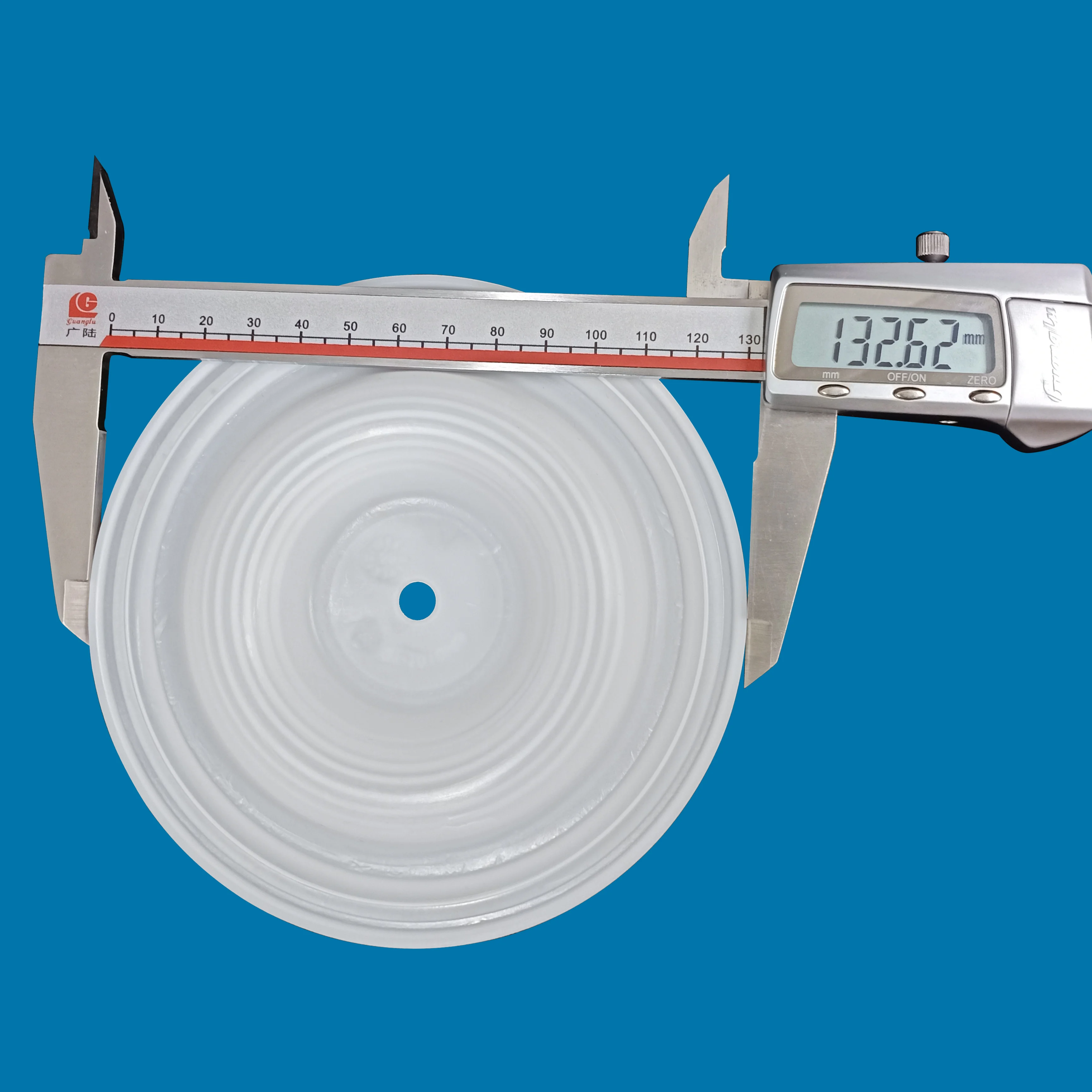

Our HNBR o rings can be used for various applications at Shanghai Chongfu. HNBR o rings are made of high quality materials and produced via advanced processes so they will perform well and have a long service life. Apart from our standard offerings, we also offer custom-made o rings which are designed in accordance with the unique requirements of our clients, thus helping them get the maximum out of our products for their applications.

Shanghai Chongfu Industry Co., Ltd. provides aggressive pricing while maintaining product quality. The company offers short shipping and delivery times, making it a reliable choice for customers who require quick turnaround times. Additionally, they ensure thorough inspection and testing of all products before shipment, ensuring that customers receive products in perfect condition.

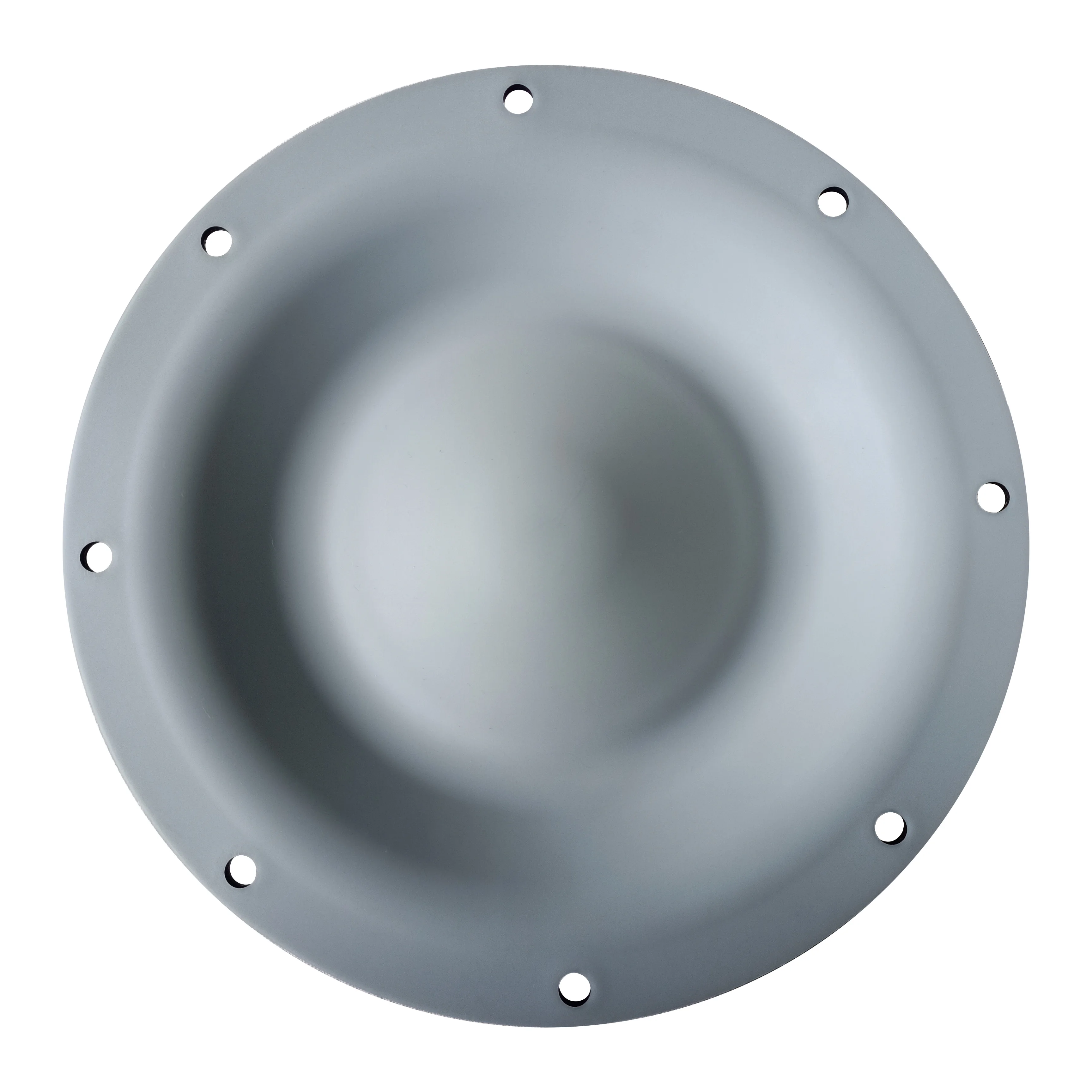

Shanghai Chongfu Industry Co., Ltd. offers a wide range of diaphragm pumps and accessories, including parts for world-renowned brands such as Wilden, Sandpiper, Almatec, Yamada, Graco, Blagdon, and Veresmatic. Their product catalog includes diaphragms, valve seats, ball valves, air valve assemblies, center bodies, shells, manifolds, shafts, mufflers, and repair kits, providing customers with a comprehensive selection of parts and pumps for various industrial needs.

With over 13 years of experience in the diaphragm pump industry, the company has developed extensive expertise in the sale of AODD (Air Operated Double Diaphragm) pump parts. They specialize in offering high-quality, reliable pump components, ensuring that their products meet industry standards and exceed customer expectations.

The company utilizes top-tier raw materials, such as American DuPont PTFE, 3M (DYGON), and Daikin from Japan, to provide their diaphragms. This ensures stable, excellent quality that meets or exceeds industry standards. The company works closely with trusted manufacturers who employ advanced production equipment and rigorous testing instruments, enabling precise quality control throughout the supply chain.