Hydraulic diaphragm pumps are nifty devices useful in the movement of liquids in factories and treatment plants. The pumps are all quite necessary to ensure everything works well. Read on to understand a little more about how diaphragm pumpss function and why they are so advantageous!

Hydraulic diaphragm metering pumps have special ways to push liquids through by power coming from the moving parts in between the pump. The pump features a flexible diaphragm that flexes back and forth, moving liquid in and out. This activity generates a vacuum, which also aids in pulling the liquid. These are the kind of pumps used in all kinds of work like water, chemicals, etc.

Hydraulic diaphragm pumps are large and one of their key advantages is their reliability. They work well with thicker or more viscous liquids that other pumps struggle to process. They are high in power and efficient, allowing them to work quickly without consuming too much energy. This makes them perfect for factories and plants where liquids need to be transferred around the clock.

The Advantages Of Using Hydraulic Diaphragm Pumps.XPATHY.pamps Which aodd pumps in Sri lanka/fwlink Honews-articles How Hydraulic drive of Pump The diaphragm pump drive is very easily achieved in different types of hydraulic work of the mashine.

They're meant to be highly efficient pumps for pumping liquid. Their design enables them to be used with various liquids without clogging. That way the factory or treatment plant can continue running without hindrance. Also, these pumps are very dependable and if properly taken care of they will last a very long time. This is necessary to keep operations going well.

Large hydraulic diaphragm pumps are used in water treatment plants. They aid in guiding dirty water through the treatment process, so that it can be cleaned and used again. The pumps can pump various chemicals and materials wastewater, and efficiently pump it through the treatment plant. This is crucial to ensure our water remains clean and safe to drink.

Because to ensure your hydraulic diaphragm pump continues to work well, you’ll need to do basic maintenance. This would involve inspecting for leaks or damage, flushing any debris that may have gotten stuck in the pump and ensuring the diaphragm is in good condition. You can help your pump last a long time by caring for it.

The company utilizes top-tier raw materials, such as American DuPont PTFE, 3M (DYGON), and Daikin from Japan, to provide their diaphragms. This ensures stable, excellent quality that meets or exceeds industry standards. The company works closely with trusted manufacturers who employ advanced production equipment and rigorous testing instruments, enabling precise quality control throughout the supply chain.

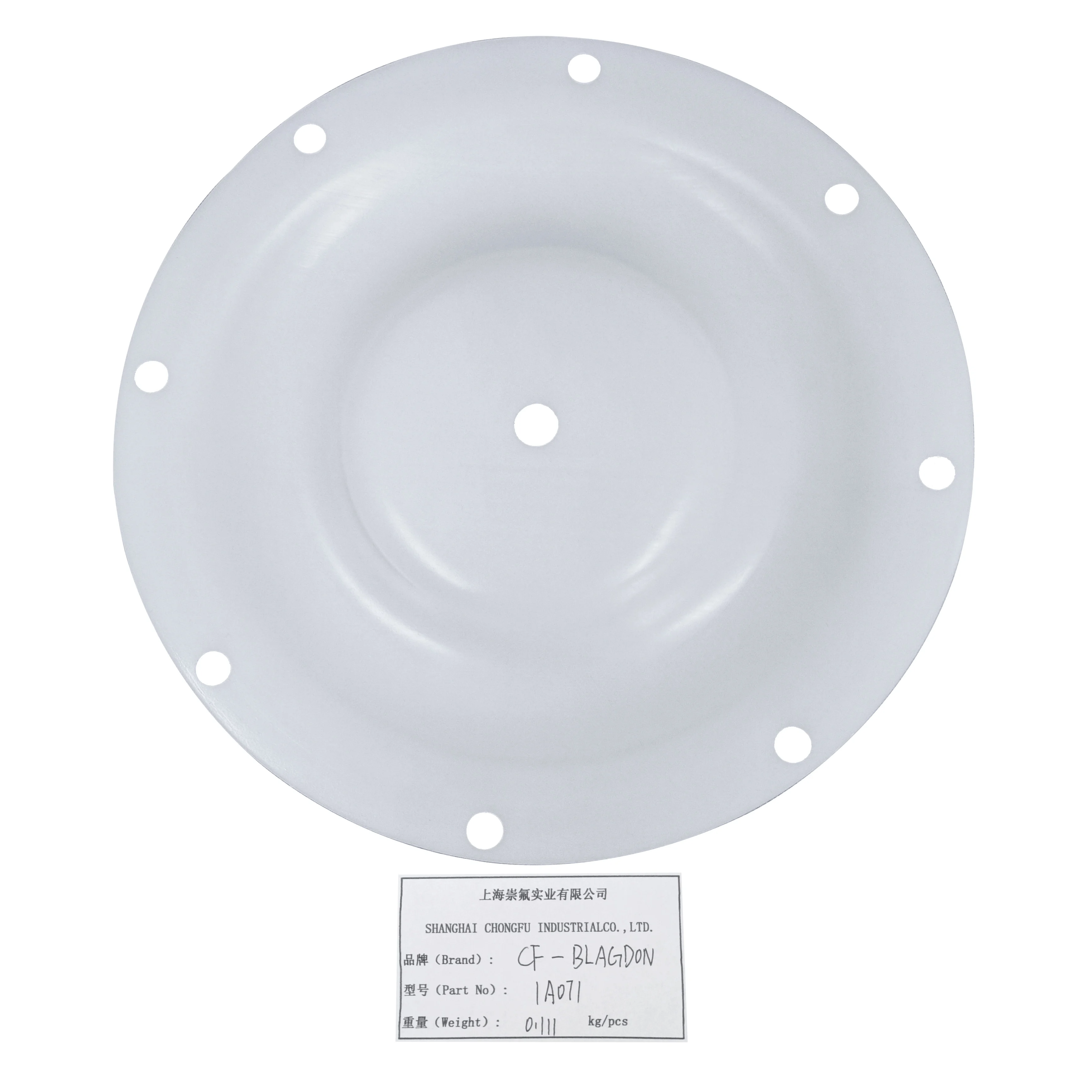

Shanghai Chongfu Industry Co., Ltd. offers a wide range of diaphragm pumps and accessories, including parts for world-renowned brands such as Wilden, Sandpiper, Almatec, Yamada, Graco, Blagdon, and Veresmatic. Their product catalog includes diaphragms, valve seats, ball valves, air valve assemblies, center bodies, shells, manifolds, shafts, mufflers, and repair kits, providing customers with a comprehensive selection of parts and pumps for various industrial needs.

With over 13 years of experience in the diaphragm pump industry, the company has developed extensive expertise in the sale of AODD (Air Operated Double Diaphragm) pump parts. They specialize in offering high-quality, reliable pump components, ensuring that their products meet industry standards and exceed customer expectations.

Shanghai Chongfu Industry Co., Ltd. provides aggressive pricing while maintaining product quality. The company offers short shipping and delivery times, making it a reliable choice for customers who require quick turnaround times. Additionally, they ensure thorough inspection and testing of all products before shipment, ensuring that customers receive products in perfect condition.