A flat rubber gasket o ring is used to even out the metal surfaces and to prevent the leaking of any liquids or gases from a pipe or a machine. These tiny rings are super beneficial in situations out there! In this guide, we will go over what these o rings are, how to find them, how to choose the right ones, how to properly look after them, and what factors of buying you should consider before making a buying decision.

Flat rubber gasket o rings are basically a small circle of rubber. It can be squished flat or pulled tight to seal a crack. These serve to form a tight seal between two surfaces that must be in close contact with each other. Made with either a round or square ring, depending upon which the machine or project calls for.

Flat rubber gasket o rings are great because they can make a tight seal without just being squeezed into place. Rubber is flexible enough to fill the gaps in which it is needed and make a good seal. This versatility and durability make these rings extremely practical for a variety of situations.

Car Engines: Several areas of car engines must remain closed in order to prevent oil, coolant or air whilst leaking. Flat rubber gasket o rings provide maximum tightness and sealing of these components in the engine even as the engine gets hot. They are quite crucial for the safe and proper working of a car.

Aerospace and Armed Forces - Flat rubber gasket o rings are used in high-tech vessels such as space shuttles, airplanes and submarines These rings have to withstand rugged environments such as high temps and vibrations.” They are vital to maintaining these gifts of technology safe and in business.

Size and Shape: The first step is to measure the diameter (the distance across the circle) and thickness of the surface on which the seal will be placed. Use a ruler or a specialized measuring tool called a caliper. Check for any grooves or gaps that could potentially alter size or shape of the o ring required

Material and Hardness: Selecting a material that can withstand the heat, pressure, and chemicals it would encounter while in use is a key consideration. Flat rubber gasket o rings are typically made from Nitrile, Silicone, or Neoprene. Rubber hardness is measured with a durometer and can range from 40 to 90. This indicates how soft/hard the rubber is.

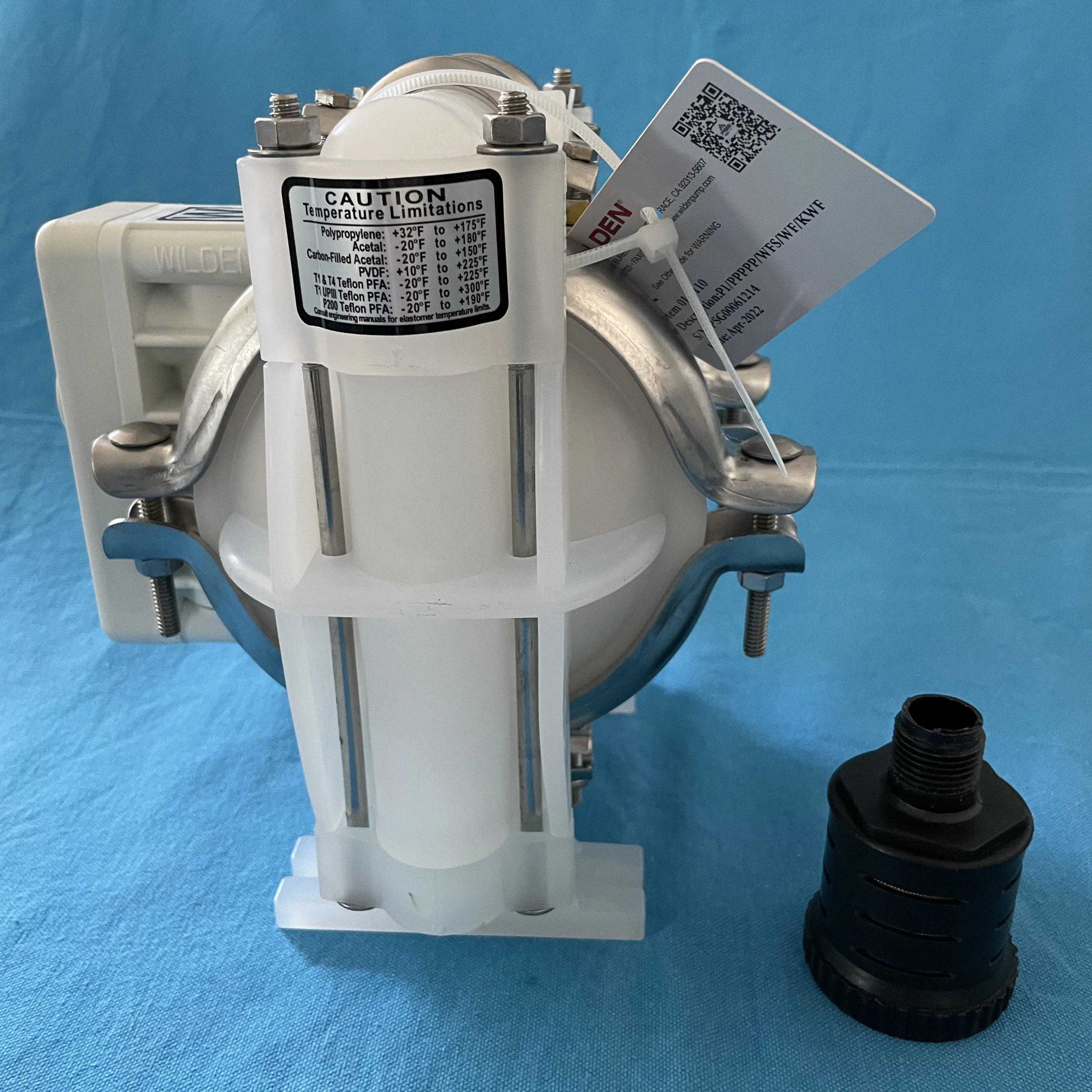

Shanghai Chongfu Industry Co., Ltd. offers a wide range of diaphragm pumps and accessories, including parts for world-renowned brands such as Wilden, Sandpiper, Almatec, Yamada, Graco, Blagdon, and Veresmatic. Their product catalog includes diaphragms, valve seats, ball valves, air valve assemblies, center bodies, shells, manifolds, shafts, mufflers, and repair kits, providing customers with a comprehensive selection of parts and pumps for various industrial needs.

The company utilizes top-tier raw materials, such as American DuPont PTFE, 3M (DYGON), and Daikin from Japan, to provide their diaphragms. This ensures stable, excellent quality that meets or exceeds industry standards. The company works closely with trusted manufacturers who employ advanced production equipment and rigorous testing instruments, enabling precise quality control throughout the supply chain.

Shanghai Chongfu Industry Co., Ltd. provides aggressive pricing while maintaining product quality. The company offers short shipping and delivery times, making it a reliable choice for customers who require quick turnaround times. Additionally, they ensure thorough inspection and testing of all products before shipment, ensuring that customers receive products in perfect condition.

With over 13 years of experience in the diaphragm pump industry, the company has developed extensive expertise in the sale of AODD (Air Operated Double Diaphragm) pump parts. They specialize in offering high-quality, reliable pump components, ensuring that their products meet industry standards and exceed customer expectations.