Today, when we think about the way machines and other technology work, we think of large machines with many components that come together to function. These machines can do wonderful things, but they also have small components that are very powerful nonethless. One of these small but important parts is the FKM diaphragm. So, let’s talk about what they’re all about and why we should care!

An FKM diaphragm is a round piece of fluoroelastomer (FKM), a special type of rubber. This is a very powerful and versatile rubber. It withstands scorching hot or boiling temperatures without failure. It also can stand up to some harsh chemicals that may damage other materials. This property makes FKM dampers very beneficial in many applications.

FKM diaphragms, for example, can be found in an assortment of places, such as automobiles, airplanes, or electronic devices. These components are frequently employed in pumps—devices that facilitate the movement of liquids—and valves—mechanisms that regulate the flow of said liquids. The diaphragm plays a vital role: it helps form a seal between two spaces. Such seals prevent liquids from leaking out and facilitate their smooth moving from one area to another. And without FKM diaphragms, a lot of machinery simply wouldn't run as smoothly!

On the downside, there are some disadvantages to FKM diaphragms as well. One drawback is that they may be more costly than other kinds of diaphragms. This also implies that their utilization can heighten the expense of manufacturing machinery. Plus, they are not as pliable as the bulk of other materials. This implies they are not the most suitable lift for each and every type of fluid control application.

Considerations When Selecting an FKM Diaphragm for a Specific Application So first of all, you need to think about the temperature that the diaphragm will be exposed to. Various FKM types react differently in numerous temperature ranges, and you, therefore, want to use one that can handle the application at the temperature it will be under.

As with any high-performance machine component, FKM diaphragms require routine maintenance and care. This means routine cleanings, and inspection is needed to make sure things are working correctly. If any damage or wear is detected, then it is important to immediately replace fill that diaphragm to prevent leaks or other issues.

A major benefit of FKM diaphragms is their software and automation system controllability. Logistics companies rely on these Smart doors because they can be automated to open and shut at certain times, removing human error and making everything run smoother. For instance, specific fluid control can help ensure better manufacturing plant production rates with fewer mistakes.

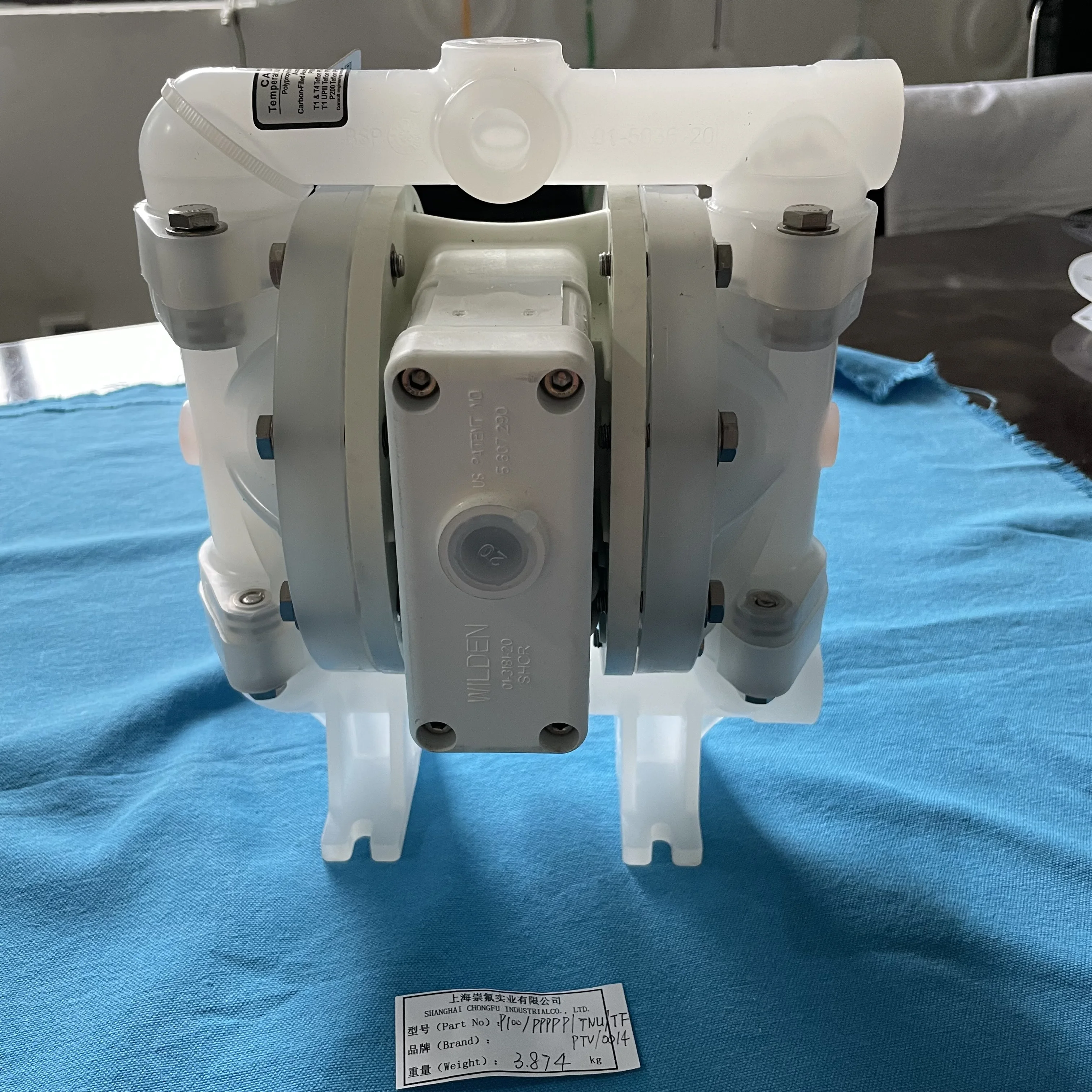

Shanghai Chongfu Industry Co., Ltd. offers a wide range of diaphragm pumps and accessories, including parts for world-renowned brands such as Wilden, Sandpiper, Almatec, Yamada, Graco, Blagdon, and Veresmatic. Their product catalog includes diaphragms, valve seats, ball valves, air valve assemblies, center bodies, shells, manifolds, shafts, mufflers, and repair kits, providing customers with a comprehensive selection of parts and pumps for various industrial needs.

The company utilizes top-tier raw materials, such as American DuPont PTFE, 3M (DYGON), and Daikin from Japan, to provide their diaphragms. This ensures stable, excellent quality that meets or exceeds industry standards. The company works closely with trusted manufacturers who employ advanced production equipment and rigorous testing instruments, enabling precise quality control throughout the supply chain.

With over 13 years of experience in the diaphragm pump industry, the company has developed extensive expertise in the sale of AODD (Air Operated Double Diaphragm) pump parts. They specialize in offering high-quality, reliable pump components, ensuring that their products meet industry standards and exceed customer expectations.

Shanghai Chongfu Industry Co., Ltd. provides aggressive pricing while maintaining product quality. The company offers short shipping and delivery times, making it a reliable choice for customers who require quick turnaround times. Additionally, they ensure thorough inspection and testing of all products before shipment, ensuring that customers receive products in perfect condition.