A twin diaphragm pneumatic pump is a unique kind of pump that uses air pressure to move fluids from one location to another. It is commonly applied in factories for transmitting various sorts of liquids such as chemicals or paints or dirty water.

A double diaphragm pneumatic pump is comprised of two large parts that move back and forth, those big parts are known as diaphragms. This motion sets off a vacuum that draws in liquid from one end and pushes it out the other. Compressed air drives the motion, hence pneumatic pump. Opening and closing valves determine the movement of the liquid in the correct direction.

The use of a electric double diaphragm pump: It can not only deliver thin liquids, but also deliver liquids with high viscosity. This means it can be a versatile option for various jobs within factories. Easy to operate and maintain are its other advantages, and therefore it is welcomed in many factories and workhops.

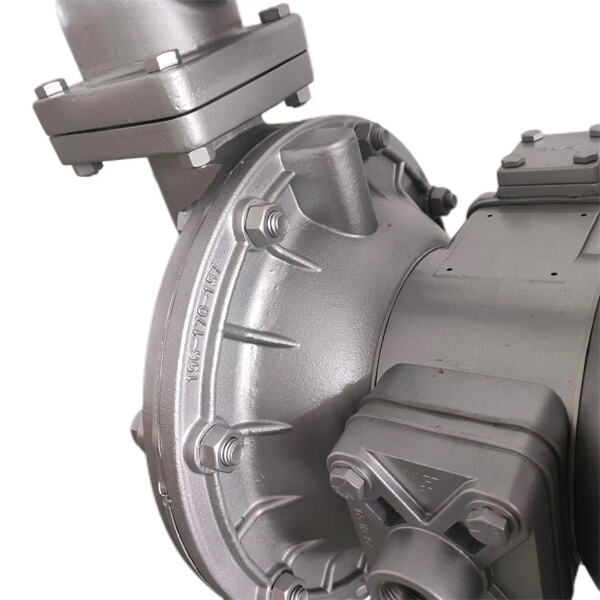

Several major components of a double diaphragm pneumatic pump are the diaphragms themselves, the valves used to regulate liquid movement, and the air compressor that supplies the pressure to operate the diaphragms. Some pumps also include additional features, including adjustable flow rates and seals to prevent spills.

To ensure the good after using the double diaphragm pneumatic pump we need to properly maintain it. This includes the periodic cleaning and inspection of the diaphragms, valves, and seals, to ensure they are in good shape. And if the pump does begin to have issues, troubleshooting tactics can range from looking for leaks to replacing worn-out parts or making sure the air pressure is at the proper level.

Double diaphragm pneumatic pumps have a host of advantages, but they are not always the right fit. For one, they don't move a lot of liquid long distances as efficiently as centrifugal pumps do. They are, however, a popular choice because they can accommodate a wider variety of liquids and lend themselves well to end-use applications where space and resources may be minimal.