A diaphragm pump is a unique type of pump that aids in the transfer of fluids from one location to another. It does this with a flexible part known as a diaphragm. The diaphragm creates the movement by forcing the liquid through the pump. Such pumps are quite forked. They are used in food factories, medicine factories, and even in mining. They are built tough and able to manage liquids that other pumps can't. But for diaphragm pumps to work properly, they require a certain level of air called air consumption.

Air requirements — This largely depends on 1 diaphragm pump design. A few things at play here. For instance, the diaphragm size matters. A bigger diaphragm can push more liquid, but it’ll require more air, too. So too are how far the diaphragm travels and how much pressure is required to push the liquid through the pump. All of these factor into our knowledge of how much air the pump needs. Air consumption may vary in diaphragm pumps of different sizes and designs. In general, larger pumps will use more air, and smaller pumps less.

Dollars per liter per minute This performance value is called displacement per cycle (DPC) and is measured in milliliters (ML). So you perform this calculation, and you learn the pump's flow rate in milliliters per minute (MLPM).

Diaphragm pumps can also consume a great deal of air, resulting in increased operating costs. But there are several intelligent steps you can take to reduce air consumption, saving you money in the long run. Here are some good tips:

Use a smaller pump A a smaller diaphragm pump 3 will consume less air if you choose to purchase a smaller one. It is capable of performing all the same functions as a larger pump, which leads to a substantial cost-saving in the long run.

Preserve the pump: Maintenance is the key! "Maintaining a clean and well-lubricated pump should help avoid clogging and/or premature wear failure. A properly maintained pump will operate more efficiently, consuming less air.

How much a diaphragm pump costs to run, for example, is highly influenced by air consumption. If a 1 inch diaphragm pump consumes excessive air, then its operating costs will increase, and it can become an island in the company’s budget. Proceeding with applications, much air can also reduce the performance of the pump; it won’t work as efficiently and as effectively as it should have. So, the air consumption should be monitored to keep everything on the right track.

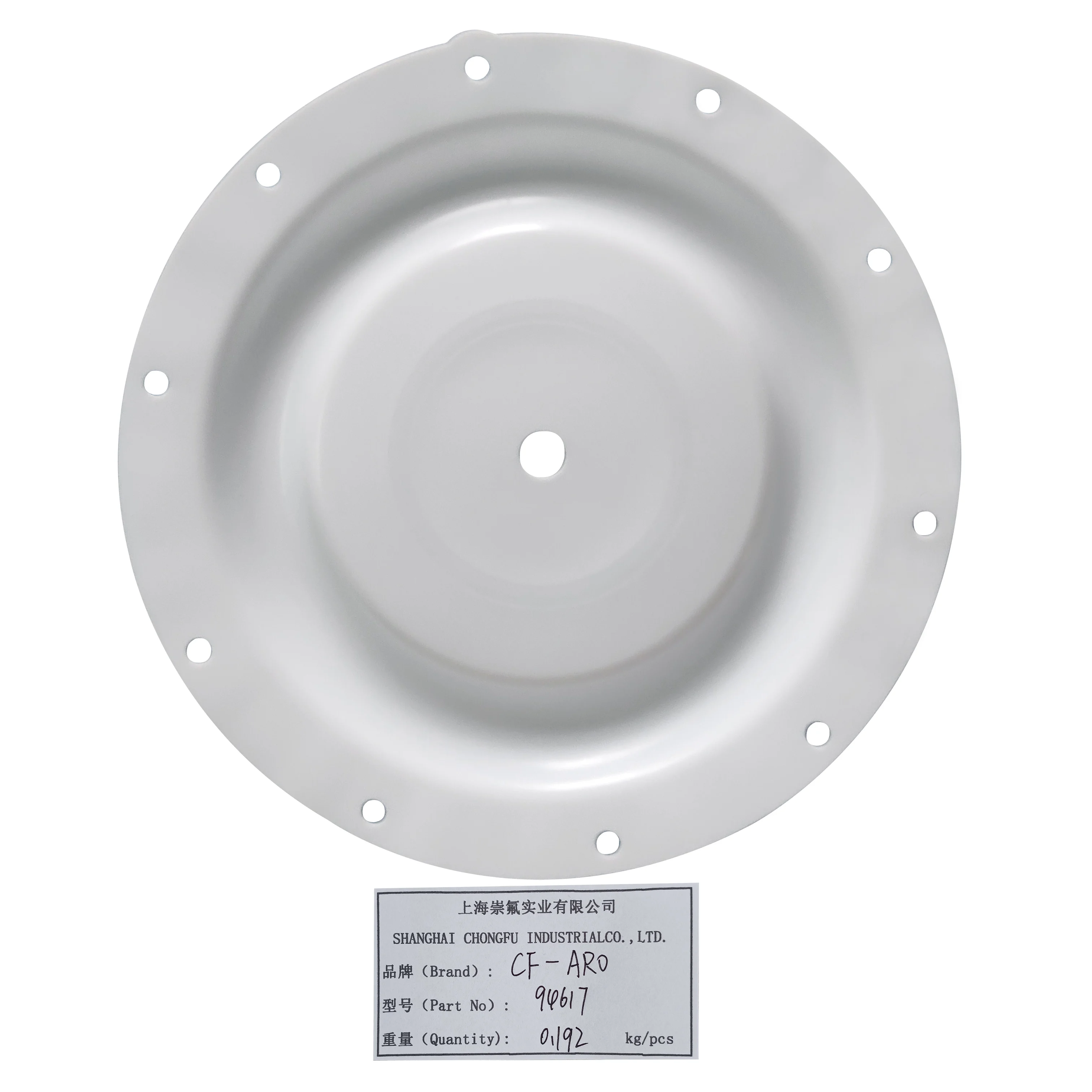

With over 13 years of experience in the diaphragm pump industry, the company has developed extensive expertise in the sale of AODD (Air Operated Double Diaphragm) pump parts. They specialize in offering high-quality, reliable pump components, ensuring that their products meet industry standards and exceed customer expectations.

Shanghai Chongfu Industry Co., Ltd. offers a wide range of diaphragm pumps and accessories, including parts for world-renowned brands such as Wilden, Sandpiper, Almatec, Yamada, Graco, Blagdon, and Veresmatic. Their product catalog includes diaphragms, valve seats, ball valves, air valve assemblies, center bodies, shells, manifolds, shafts, mufflers, and repair kits, providing customers with a comprehensive selection of parts and pumps for various industrial needs.

Shanghai Chongfu Industry Co., Ltd. provides aggressive pricing while maintaining product quality. The company offers short shipping and delivery times, making it a reliable choice for customers who require quick turnaround times. Additionally, they ensure thorough inspection and testing of all products before shipment, ensuring that customers receive products in perfect condition.

The company utilizes top-tier raw materials, such as American DuPont PTFE, 3M (DYGON), and Daikin from Japan, to provide their diaphragms. This ensures stable, excellent quality that meets or exceeds industry standards. The company works closely with trusted manufacturers who employ advanced production equipment and rigorous testing instruments, enabling precise quality control throughout the supply chain.