It’s important to know the basics of how diaphragm pumps operate as they are used to move liquids in a wide range of applications. Diaphragm pumps rely on a flexible piece known as a diaphragm, which flexes and stretches. This creates pressure to force the liquid through the pump and into hoses or other storage vessels.

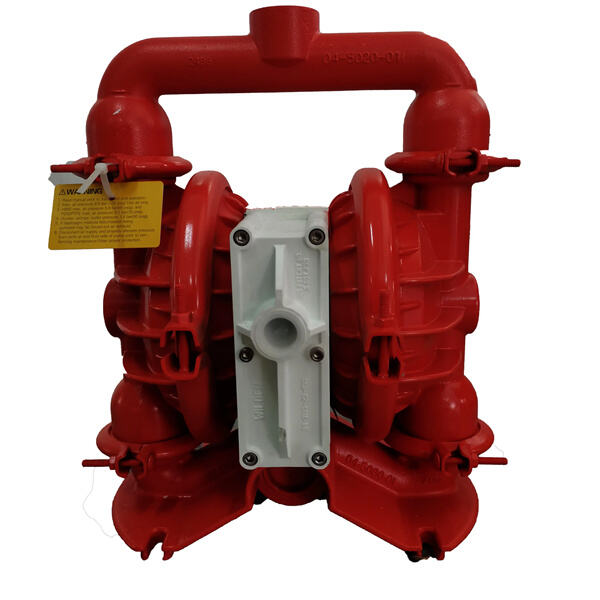

Diaphragm pumps come in two types, and understanding the differences between them can help us choose the right one for a job. The diaphragm pump 1 has a single reciprocating diaphragm. It generates suction and pressure. Diaphragm pump 2 is comprised of a pair of diaphragms working in unison. This enables it to develop more pressure and pump more liquid.

The two pumps help in opposite aspects. Diaphragm pump 1 comes in handy when we’re doing small jobs or when we want a slower flow. Diaphragm pump 2 is ideal for larger jobs with higher flow rates and more pressure. Either pump is powerful, reliable and adaptable.

In order to keep diaphragm pump 1 and 2 function properly then we have to take care of it. The diaphragms are to be monitored for damage, leaks, and the cleanliness of the pump should be maintained. This helps prevent costly repairs and extends the life of your pump. We also should heed the manufacturer’s guidance about how to care for our pumps and how to use them.

Diaphragm pumps 1 and 2 have a wide range of applications. Diaphragm pump 1 is specifically employed in farming, car repair, food production. It can be used to process a variety of liquids, including water, oil and chemicals. Diaphragm pump 2 is typically employed in larger jobs including mining, construction, and oil work. It is good for pumping thick or gritty fluid, since more pressure and flow are developed.