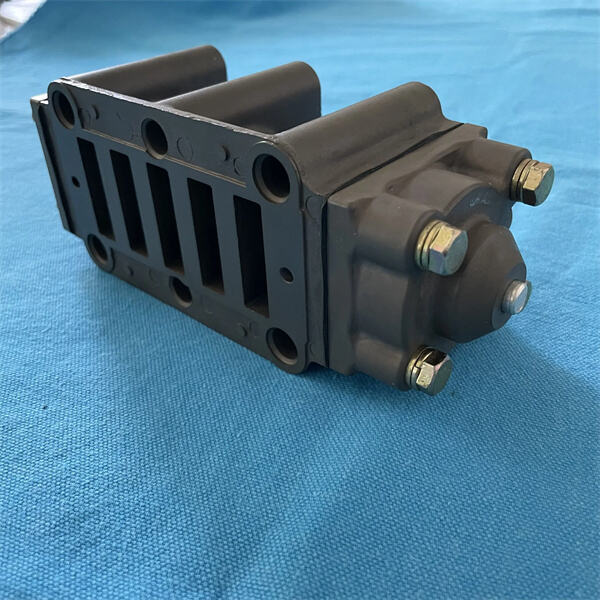

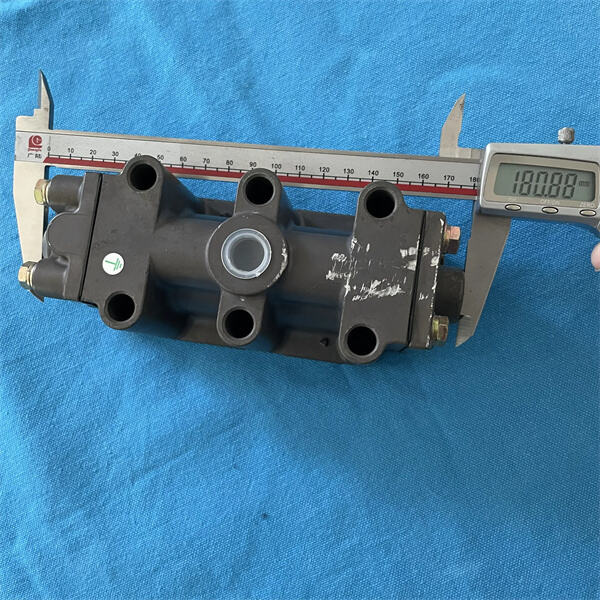

An air valve assembly consists of the following components: valve body, valve stem, springs, diaphragm and seals. The valve body is akin to the housing that contains everything else. The valve stem rises and falls to regulate the way air moves. Springs assist opening and closing of the valve; the diaphragm augments the springs to manage air pressure. Seals are crucial, because they contain the air and help everything function properly.

First, you’ll want to have all the equipment you’ll need. Be sure to follow the directions in assembling the air valve assembly. Be aware of how the pieces fit into place and double check that everything is tight before testing the system.

Proper maintenance is essential to keep your air valve assembly in good condition. Search for any signs of damage, such as drips or odd noises. Frequently clean the assembly to avoid the dust and dirt that will fuck things up. Address any problems quickly before they get worse.

Air valve assemblies control the air pressure and make the system operate with efficiency and without any mishap. They seal air leaks, and they provide an unimpeded stream of air, which is essential to making sure the system runs efficiently in industrial settings.

If there is leakage of air in the assembly, it is due to the seal(s) or diaphragm damaged. Replace any broken parts to prevent further leakage. If the valve isn’t opening or closing properly, check the springs and the valve stem to see if anything is obstructing them. If necessary, clean out these parts, or replace them, to ensure everything works correctly.

If you’re getting a weak flow of air, or no consistent flow at all, take a look at the connections and the hoses to see if they’re blocked or leaking anywhere. Be certain that there is sufficient pressure in the system and the air valve assembly is functioning properly. If you continue to have trouble, seek out a professional.

Newer air valve assemblies are made to last longer and consume less energy than older paper ones. They are built with better materials and technology so they work better and last longer. With an upgrade you will experience faster response times, increased precision, and reduced maintenance costs.