Hello, friends! Have you ever heard about air driven diaphragm pumps? They may seem fancy and complicated, but they are very simple once you figure out how they work. One of those important tools is these pumps and it helps us to push these liquids, could be water, through the long tubes. They go into all kinds of places, from laboratories to hospitals, to help direct where liquids should (and shouldn’t) go. Let’s explore air driven peristaltic pumps and how they work!

There are important components of air driven peristaltic pump and they all work in unison with each other. There is a first is a tube or hose that the liquid travels up. TRANSLATION – FLUIDS FLOW THROUGH A SPECIFIC TUBE Then, rollers compress the tube tightly. Then an air compressor, which pumps air into the pump, which controls the rollers.

After the roller passes over the liquid, it closes the tube tight. This action forces the liquid out of the pump and through the tube. And this cycle continues, and continues. The rollers press the tube to draw in the fluid and release it to expel it. This is what allows the pump to continuously pass the liquid down the tube without faltering.

Now we know how air driven peristaltic pumps work, let’s explore when we like to use them. One major advantage of these pumps is their high accuracy. Because they use rollers to control the amount of liquid that goes through the tube, you can meter exactly how much liquid goes through. It is very useful when required to use the precise volume for something, such as in chemical labs or using medicine where there is no alternative such as without water.

Air driven peristaltic pumps also have the additional benefit of being extremely gentle on liquid being pumped. Because the liquid only comes into contact with the inside of the tube and not with any other moving parts, it doesn’t get spoiled or mixed with anything else. That is crucial for applications, such as food processing or medical applications, where we don’t want to spoil the liquid or change its properties. Thus, in food production, it is crucial to maintain the purity of the raw materials for food safety and quality.

Application of air driven peristaltic pumps in several fields One widespread application is in laboratories, where they assist scientists with the accurate and gentle manipulation of liquids. This allows them to combine chemicals without resulting in any negative reactions. They are used in the food and drink industry, too, to transfer ingredients or mixtures from one location to another. Just imagine how much simpler both of those elements are when the pumps can precisely control how much beverage is dispensed!

Regular maintenance goes a long way in keeping the air driven peristaltic pumps functioning proper and at their most efficient just like any other machine. A critical step is to regularly clean the tube and rollers. This ensures that there are no oil clogs or blockages that can prevent the pump from functioning properly. You also need to exchange out the tube frequently to avoid it from breaking down over time. A tired tube can impact the performance of the pump.

The company utilizes top-tier raw materials, such as American DuPont PTFE, 3M (DYGON), and Daikin from Japan, to provide their diaphragms. This ensures stable, excellent quality that meets or exceeds industry standards. The company works closely with trusted manufacturers who employ advanced production equipment and rigorous testing instruments, enabling precise quality control throughout the supply chain.

With over 13 years of experience in the diaphragm pump industry, the company has developed extensive expertise in the sale of AODD (Air Operated Double Diaphragm) pump parts. They specialize in offering high-quality, reliable pump components, ensuring that their products meet industry standards and exceed customer expectations.

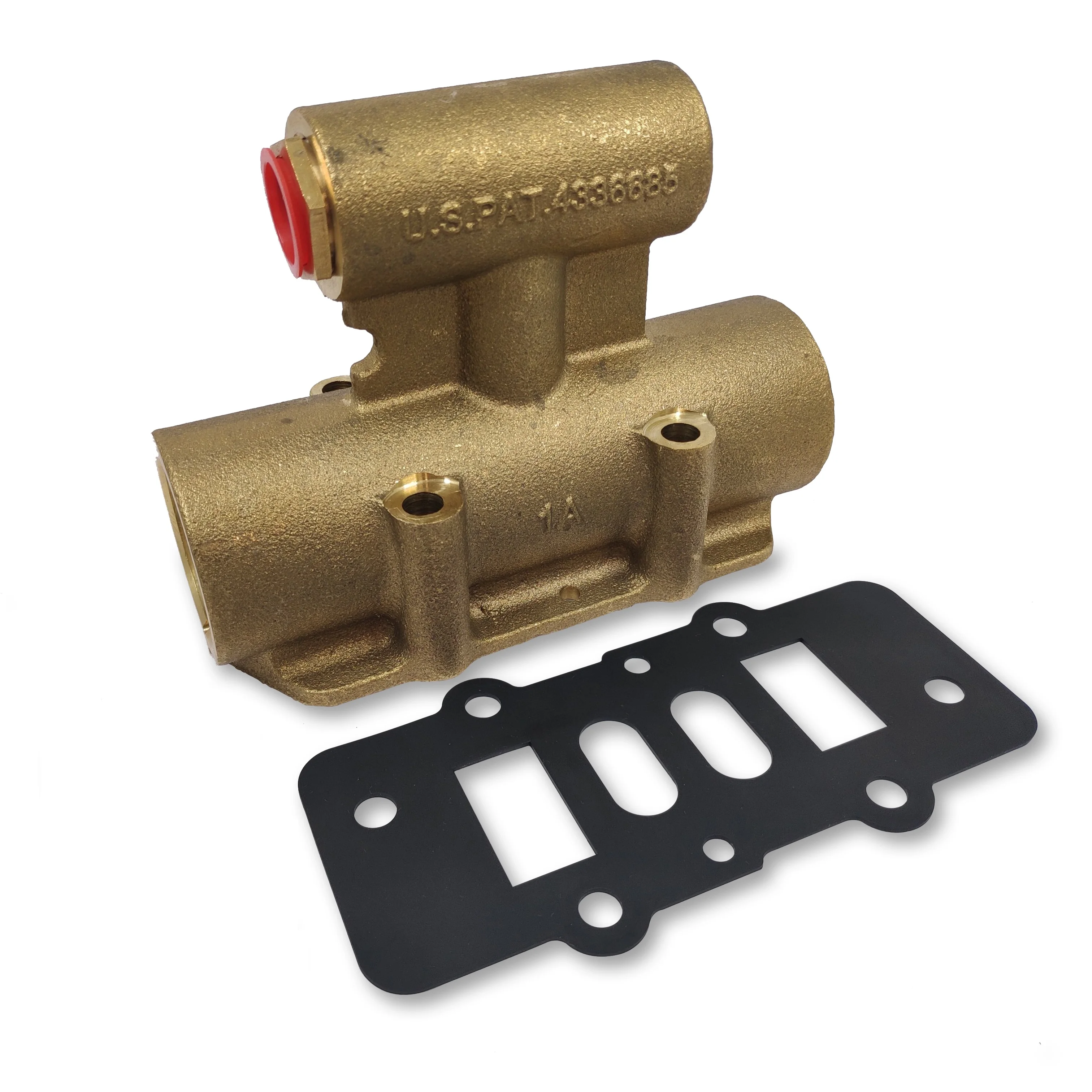

Shanghai Chongfu Industry Co., Ltd. offers a wide range of diaphragm pumps and accessories, including parts for world-renowned brands such as Wilden, Sandpiper, Almatec, Yamada, Graco, Blagdon, and Veresmatic. Their product catalog includes diaphragms, valve seats, ball valves, air valve assemblies, center bodies, shells, manifolds, shafts, mufflers, and repair kits, providing customers with a comprehensive selection of parts and pumps for various industrial needs.

Shanghai Chongfu Industry Co., Ltd. provides aggressive pricing while maintaining product quality. The company offers short shipping and delivery times, making it a reliable choice for customers who require quick turnaround times. Additionally, they ensure thorough inspection and testing of all products before shipment, ensuring that customers receive products in perfect condition.