Question: Have you ever think of how we transport water, chemical or oil from one place to another? That seems like a simple task — but requires special tools. You probably have a diaphragm pump which is one of these tools. We will end up with the diaphragm pumps which is a particular type of diaphragm pump which we will explore further today. We will look at how it works and why it is so useful for transferring various types of liquids.

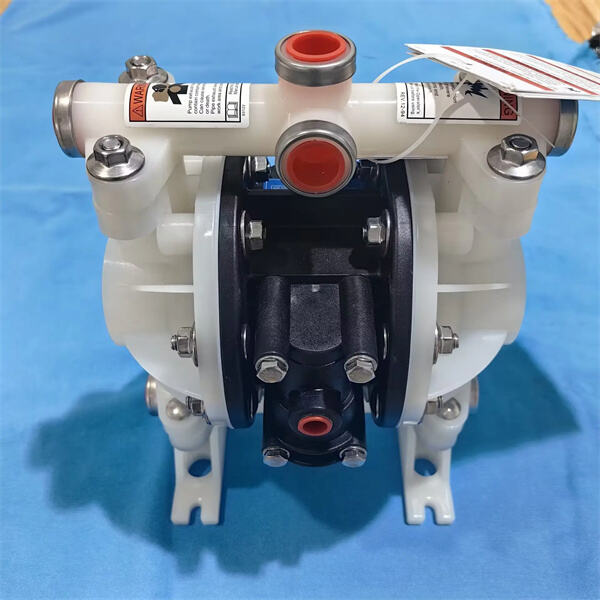

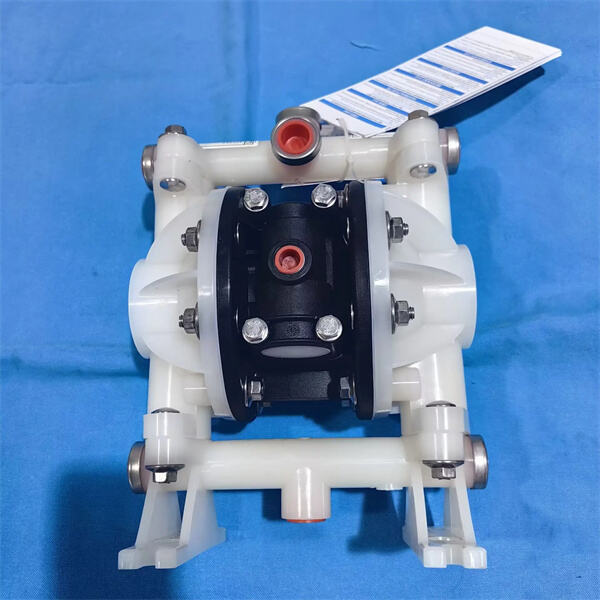

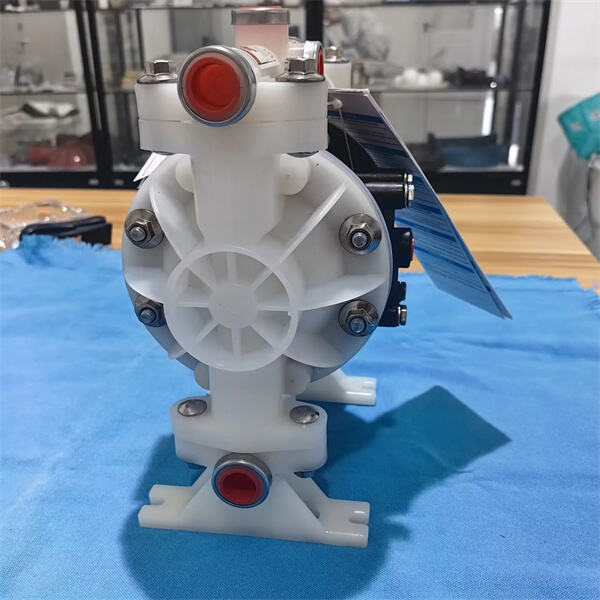

For high performance, the 1 1 2 diaphragm pump moves fluids using a diaphragm. How does it do that? Well, it has a component known as a diaphragm. This diaphragm is a stretchy material that moves back and forth. When the diaphragm moves downward, it creates a vacuum that sucks the liquid inside; when it moves back up, it pushes the liquid out. The back-and-forth motion creates suction and pressure that pushes fluids into and out of the pump.

The diaphragm pump for sale has one great advantage: it is able to perform differently depending on the liquids. It can do clean water, thick oil, even some chemicals. This flexibility allows it to be very useful in numerous scenarios. Also, the pump icon has a variable flow rate. That means you can vary how much fluid you’d like to displace per action. Whether you need to adjust a little or a lot, the pump can be set according to your needs.

Applications of the 1 1 2 Diaphragm pump: The 1 1 2 diaphragm pump is also a very versatile tool including a wide range of places. Such as in farming, moving water from wells or rivers for irrigation (watering crops) This pump is also very useful in construction. It is used to transfer concrete or grout, which are essential for making structures and setting up strong foundations.

And despite its uses in agriculture, construction, and mining, the 1 1 2 diaphragm pump also aids in cleansing. For example, it is capable of spraying pesticides to protect the health of the plants or pumping wastewater to keep our living environment clean and free from hazards. This versatility demonstrates the application of this pump across various sectors.

Pumping liquids often requires a good reliable and solid pump. That demands a real durable device able to work in some difficult conditions and its breaking down should be avoided. Designed from durable materials of cast iron or stainless steel, 1 1 2 diaphragm pump They are also resistant to rust, wear, and damage, allowing the pump to be used for years, even in the harshest conditions.

The 1 1 2 diaphragm pump has is it has very low maintenance costs and easy to repair. And if something doesn’t work or if a piece needs to be replaced, you don’t have to stress about dismantling the whole pump. The pump features a modular design, allowing you to easily swap out individual parts. The diaphragm, for example, if it dies you can pull it out by removing the clamps that are securing it and insert a new one.

Shanghai Chongfu Industry Co., Ltd. offers a wide range of diaphragm pumps and accessories, including parts for world-renowned brands such as Wilden, Sandpiper, Almatec, Yamada, Graco, Blagdon, and Veresmatic. Their product catalog includes diaphragms, valve seats, ball valves, air valve assemblies, center bodies, shells, manifolds, shafts, mufflers, and repair kits, providing customers with a comprehensive selection of parts and pumps for various industrial needs.

With over 13 years of experience in the diaphragm pump industry, the company has developed extensive expertise in the sale of AODD (Air Operated Double Diaphragm) pump parts. They specialize in offering high-quality, reliable pump components, ensuring that their products meet industry standards and exceed customer expectations.

Shanghai Chongfu Industry Co., Ltd. provides aggressive pricing while maintaining product quality. The company offers short shipping and delivery times, making it a reliable choice for customers who require quick turnaround times. Additionally, they ensure thorough inspection and testing of all products before shipment, ensuring that customers receive products in perfect condition.

The company utilizes top-tier raw materials, such as American DuPont PTFE, 3M (DYGON), and Daikin from Japan, to provide their diaphragms. This ensures stable, excellent quality that meets or exceeds industry standards. The company works closely with trusted manufacturers who employ advanced production equipment and rigorous testing instruments, enabling precise quality control throughout the supply chain.